2026 Global TPU Market Outlook: Navigating Regulations & Supply Chain Shifts

By GREEN TPU Strategic Market Team | Based on Source Manufacturer Insights

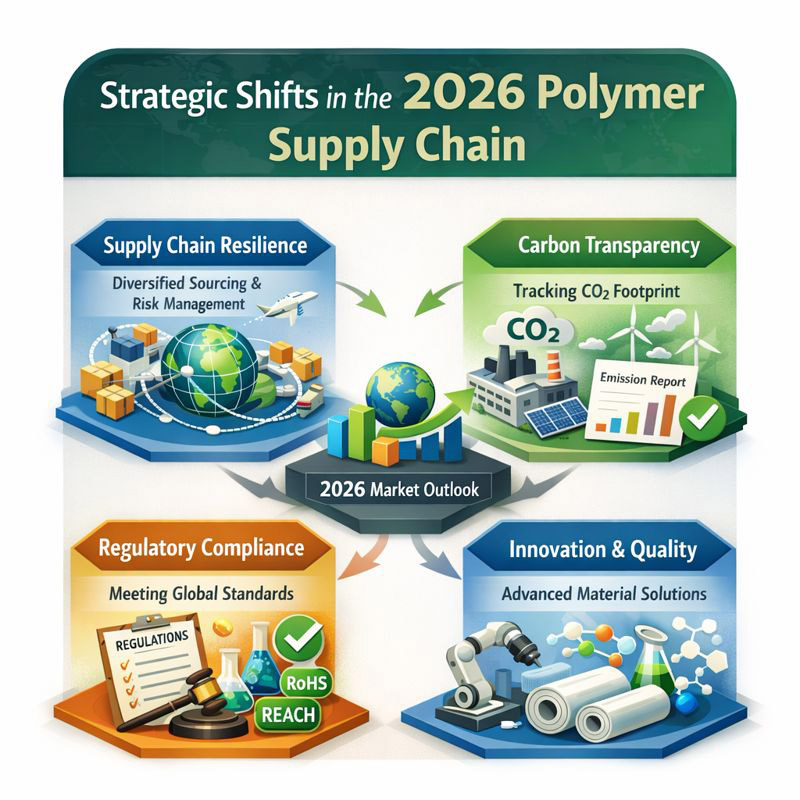

As we approach 2026, the global polymer materials market is undergoing a profound structural transformation. The era of competing solely on price is over. For B2B procurement in automotive seating, medical, and textile sectors, the new battlegrounds are Supply Chain Resilience, Carbon Transparency, and Regulatory Compliance.

At GREEN TPU, positioned as a premier Advanced Material Manufacturer and ISO-certified entity, we leverage decades of extrusion expertise to help global clients adapt to these macro-environmental changes. This report analyzes the 2026 market landscape and demonstrates how our verified qualifications mitigate your procurement risks.

Strategic shifts in the 2026 Polymer Supply Chain

Part 1: The 2026 Market Environment & Challenges

Three major forces are reshaping how TPU films are sourced and traded globally. We have broken these down into critical insights:

1. The "Green" Wall

Market Shift: By 2026, EU regulations like ESPR and CBAM will penalize non-sustainable materials.

Your Risk: Heavy tariffs or exclusion for using undocumented plastics.

2. Deep Traceability

Market Shift: The "Digital Product Passport" (DPP) is becoming reality. Origins must be proven.

Your Risk: Relying on middlemen who cannot provide batch-level data.

3. Supply De-Risking

Market Shift: Cost volatility requires suppliers with robust inventory management.

Your Risk: Production stoppages due to supplier instability.

Green TPU's Strategic Response: Inventory Security

To combat supply chain volatility, we have implemented a Strategic Resin Reserve System. Unlike traders who buy spot market materials, we maintain long-term contracts with tier-1 international resin manufacturers. This ensures that even during global shortages, our production lines—and your orders—keep running without interruption.

Part 2: GREEN TPU’s Compliance Shield (Verified Trust)

To navigate these market challenges, you need a partner with verified credentials. We present our 2026 Compliance Portfolio, backed by third-party testing.

Solution to Trade Barriers: Global Regulatory Compliance

| Regulatory Standard | Verification Data (SGS Reports) & Value |

|---|---|

| EU RoHS Directive (Electronics & General Import) | Compliance: Pass (No Lead, Mercury, Cadmium) Report No.: SZXEC25001831401 Value: Mandatory for all consumer electronics entering the EU market. |

| REACH Regulation (Chemical Safety) | Compliance: Pass (Screened for 235+ SVHCs) Report No.: SZXEC25001831403 Value: Ensures seat materials release no harmful substances in closed cabins. |

| Halogen-Free Standard (Green Energy & Battery Safety) | Compliance: Pass (Chlorine/Bromine Free) Report No.: SZXEC25000329001 Value: Critical for Electric Vehicle (EV) Seat Components. Ensures LSZH safety near battery packs. |

Solution to Supply Stability: Scalable Manufacturing Power

Beyond certificates, you need a partner who can deliver. We combine quality with capacity.

ISO 9001:2015 Certified

Certificate No.: U25Q2GZ8024484R1S

Process: We use advanced Cast Film & Extrusion processes.

Benefit: Guarantees standardized workflows and batch-to-batch consistency for automotive Tier 1 suppliers.

Agile Manufacturing & R&D Support

Industrial Capacity: Monthly output > 500 tons

Tiered Support System:

- Free A4 Samples (Sample Policy).

- 1 Roll Ready Stock for immediate prototyping.

- 1,000kg MOQ for exclusive OEM/ODM formulas.

Benefit: We accelerate your "Concept-to-Market" cycle, bridging the gap between R&D sampling and mass production.

Logistics & Safety Shield: Ensuring Goods Arrival

A great product is useless if it arrives damaged or stuck in customs. We implement a Heavy-Duty 5-Level Packaging Standard to solve logistics pain points:

Safe Transport Reports

We provide CNAS-certified Non-Dangerous Goods Reports and MSDS to speed up customs clearance. View Report No: 202501430512184

Heavy-Duty Protection

Our 5-Level Barrier System (EPE Foam + Waterproof Film + Woven Bag + Carton) prevents moisture and telescoping. See Packing Details

Inside the Factory: How We Control Quality

- Online Thickness Gauge: Real-time monitoring of film thickness (±0.01mm tolerance) during extrusion to ensure consistent uniformity across the entire roll.

- Expert Visual Inspection: Experienced QC technicians meticulously inspect the film surface to detect and eliminate complex defects (such as gels or black spots) that machines might miss.

- Retained Samples: We keep physical samples from every production batch for 2 years, enabling full traceability for your peace of mind.

Part 3: 2026 Technology Trends & Our Readiness

Based on our status as an Innovation-Driven Source Factory, we have aligned our R&D with the following 2026 technology trends:

Trend A: Intelligent Pneumatic Seating (Active Comfort)

As vehicles become autonomous "living rooms," static seats are being replaced by Active Pneumatic Systems (Massage airbags, Dynamic Bolsters, and Lumbar Support).

Our Readiness: Our specialized Seat Cushion TPU Films are engineered for high-frequency inflation/deflation cycles (>50,000 cycles). We have achieved a 92% Fogging Value (SGS Report CANAUTO25021862701_1). This is critical for seat interiors to prevent volatile emissions from fogging up the windshield.

Engineer's Note: Our films also feature Low-Noise (NVH) surface treatment, ensuring silent operation for massage bladders in quiet EV cabins.

Trend B: Post-Pandemic Hygiene Standards

Shared mobility and medical devices will require inherent antimicrobial properties.

Our Readiness: We have developed films with a >99.9% Antibacterial Rate (Verified by SGS Report No. CANAUTO25022531002). This effectively inhibits E. coli and S. aureus. (Check Medical Safety FAQ)

Part 4: Manufacturer Selection Strategy for 2026

When selecting a supplier for the next 5 years, use this audit checklist:

| Audit Criteria | GREEN TPU Capability |

|---|---|

| Is it a Source Factory? | Yes. We operate our own extrusion lines. See Factory Verification. |

| Is the Data Verified? | Yes. Every claim (Fogging, RoHS, REACH) is backed by specific SGS report numbers. View Reports. |

| Do they offer Tech Support? | Yes. We advise on bonding compatibility and internal lab testing. |

Conclusion: Data-Driven Confidence

The market in 2026 will be unforgiving to those who ignore compliance and sustainability. GREEN TPU offers you more than just film; we offer a Compliance Shield.

With our ISO 9001 management, scalable production capacity, and a full library of SGS reports, we are the strategic partner to future-proof your supply chain.

Audit Our Factory & Request Full Report Copies