TPU Hot Melt Adhesive Film for Automotive Interior Laminates | Superior Bonding Strength & Durability

High-performance TPU hot melt adhesive film is engineered for precision automotive interior lamination applications. Designed to ensure strong, flexible, and long-lasting adhesion between various interior materials such as fabric, leather, and foam, it delivers exceptional thermal stability and peel strength.

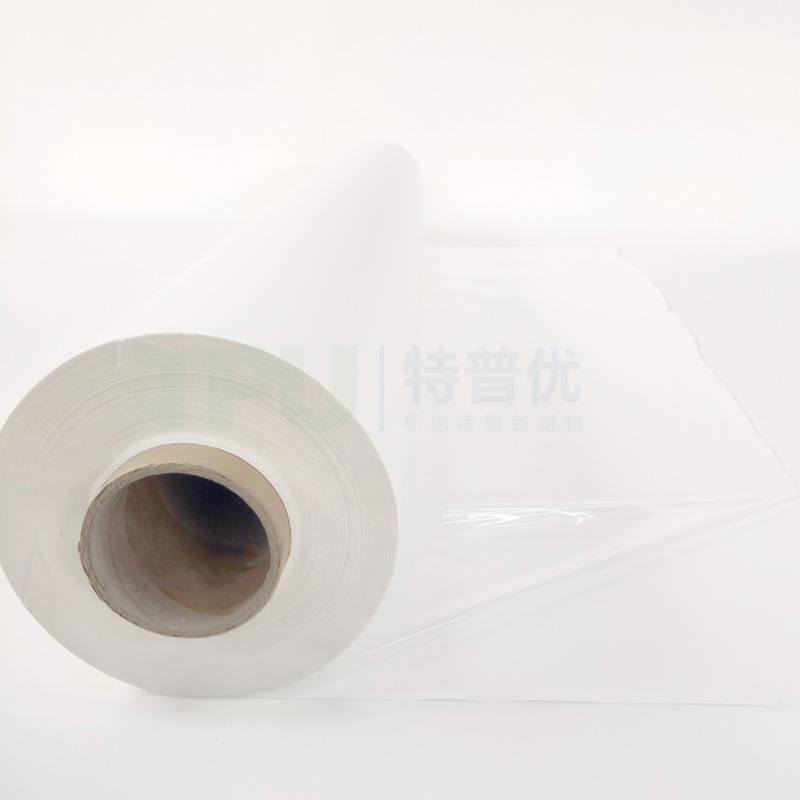

- Product Name: TPU Hot Melt Adhesive Film

- Substrate Type: Polyester Type (TPU-PE)

- Substrate Type: Polyester-based (TPU-ET)

- Adhesive film with substrate: Protected by release paper/release film

- Substrate-free adhesive film: Direct winding, no protective film

- Thickness: 0.03-2.0mm

- wide width: 152 cm, customizable to any width as required

- Color: True Colors

- Temperature range: -40°C ~ 120°C

- Environmental Certification: RoHS, REACH, Halogen, Heavy Metals

Product Application

Our TPU hot melt adhesive film is widely applied in automotive interior lamination systems. It plays a key role in revolutionizing automotive interior manufacturing by providing eco-friendly, solvent-free bonding solutions:

💺 Seat Upholstery & Foam

Provides soft-touch bonding between seat cover fabrics and foam layers. Ensures enhanced comfort and flexibility without hardening over time.

🚪 Door Panels & Trim

Ensures durable adhesion between decorative surfaces (leather/PVC) and structural plastics (ABS/PP), preventing edge lifting.

🚗 Headliner Assembly

Bonds fabric or microfiber layers to base substrates. High heat resistance prevents sagging even in extreme summer temperatures.

🛑 Carpets & Floor Systems

Secures carpet backing materials and underlayers with excellent stability, reducing noise and vibration (NVH).

📟 Dashboard Panels

Delivers uniform adhesion for leather wrapping on instrument panels, ensuring a premium, bubble-free finish.

🔇 Trunk & Soundproofing

Offers strong adhesion for multi-layer laminates used in acoustic insulation and noise reduction mats.

Why Choose Our Automotive TPU Adhesive?

Our automotive-grade TPU hot melt adhesive film is engineered to combine superior bonding strength, environmental safety, and production flexibility. Ideal for OEM and Tier 1 manufacturers.

| Key Feature | Automotive Advantage |

|---|---|

| Bonding Strength | Excellent adhesion to PVC, PET, Leather, Foam, and ABS. Prevents delamination under vibration. |

| Temp Resistance | Stable from -40°C to 120°C. No cracking in winter, no softening in summer heat. |

| Low Fogging (VOC) | Meets DIN 75201 (>90%). Low VOCs ensure clean cabin air. |

| Flame Retardant | Complies with FMVSS 302 & GB 8410. Self-extinguishing. |

| Durability | Resists UV, humidity (Hydrolysis), and aging. Maintains performance over the vehicle's lifespan. |

| Processability | Compatible with Heat Lamination, Roller Coating, and Pressing. High production efficiency. |

🏆 IATF 16949 Certified

Manufactured under ISO/IATF 16949:2016 quality management system, ensuring full traceability and consistency for global automotive OEM standards.

🔥 Flame Retardant

Complies with FMVSS 302 and GB 8410 standards. The material is self-extinguishing to ensure passenger safety.

View Fire Safety Report →

🌿 Low Fogging (Low VOC)

Meets DIN 75201 standards with a fogging value >90%. Low VOC emissions ensure clean cabin air and prevent windshield residue.

View Fogging Report →

💪 Superior Bonding

Excellent adhesion on substrates like ABS, PP, Leather, and Foam. Prevents delamination under vibration and thermal cycling (-40°C to 120°C).

Why Partner with GREEN TPU?

FAQ

Q: Are you a trading company or a manufacturer?

A: We are an integrated industry and trade company specializing in the manufacture and export of TPU film materials for over 15 years. Learn more about our factory.

Q: Can we customize performance, size, and color?

A: Yes, we accept full OEM/ODM customization to meet your specific technical requirements.

Q: Do you provide sample services?

A: Yes, we provide free samples (A4 size or trial rolls) for project validation. You only need to cover the shipping cost.