TPU Hot-Melt Adhesive Film for Footwear Material Laminating | Hydrolysis-Resistant & High Elasticity | Preferred Choice

This TPU adhesive film provides soft touch, high elasticity, and stable lamination performance, making it an ideal choice for bonding shoe uppers, linings, leather, mesh fabrics, and foam materials. It supports various processing methods, including heat pressing and flat lamination, with clean and environmentally friendly production—no solvent, no odor, and recyclable.

- Product Name: TPU Hot Melt Adhesive Film

- Substrate Type: Polyester Type (TPU-PE)

- Substrate Type: Polyester-based (TPU-ET)

- Adhesive film with substrate: Protected by release paper/release film

- Substrate-free adhesive film: Direct winding, no protective film

- Thickness: 0.03-2.0mm

- wide width: 152 cm, customizable to any width as required

- Color: True Colors

- Temperature range: -40°C ~ 120°C

- Environmental Certification: RoHS, REACH, Halogen, Heavy Metals

What is the Best TPU Film for Shoes in Modern Manufacturing?

As a professional tpu film for shoes factory, our GREEN TPU hot melt adhesive film is a sustainable driving force in the industry. Our high quality tpu film hot melt film is essential for unlocking the limitless potential of next-generation material composites. By using durable leather shoes upper tpu hot melt film, manufacturers can achieve superior bonding without toxic solvents.

👟 Sustainable Upper Composites

Our factory provides a 100% solvent-free bonding solution for mesh and leather uppers. This high-strength leather shoes upper film ensures a non-toxic production process and high stretch recovery.

- Excellent tpu film laminate stability.

- Optimized for tpu upper shoes production.

- Replaces chemical adhesives in durable leather shoes upper.

🔗 Eco-Friendly Sole Bonding

Designed for bonding sport shoes upper to rubber or EVA soles. As a high-quality tpu film for sport shoes upper supplier, we ensure permanent adhesion and prevent delamination.

- Reliable tpu hot melt adhesive film for durability.

- Anti-slip tpu film for shoes performance.

- Eco-friendly tpu film for sport shoes upper manufacturer standards.

☔ Clean Seam Sealing

Achieve reliable waterproofing without toxic liquid glues. Our waterproof manufacturer tpu film for sport shoes upper melts into fabric fibers to create a robust seal.

- Ideal for green technical and outdoor tpu footwear.

- Preferred tpu lining for moisture protection.

- High-strength leather shoes upper seam sealing.

⚙️ Green Process Optimization

Engineered for energy-efficient automated production. As a flexible manufacturer tpu film for sport shoes upper, our factory focuses on stable activation temperatures to reduce carbon footprints.

- Stable quality from a durable tpu film for shoes supplier.

- Reduces waste in tpu hot melt film assembly.

- Scalable eco-friendly tpu film for sport shoes upper company solutions.

Sustainable Performance: Why Choose GREEN TPU Factory?

As a direct manufacturer, we provide 100% recyclable and solvent-free solutions. Learn more about the truth about TPU biodegradability and recycling for modern footwear:

| Technical Advantage | Sustainable Manufacturing Benefit |

|---|---|

| 100% Solvent-Free & Durable | No harmful chemicals or odors. Our durable manufacturer tpu film supports the circular economy in tpu footwear. |

| Antibacterial Protection | Passed the Antibacterial Test (>99.9%) for long-term hygiene. |

| Halogen-Free Compliance | Certified Halogen-Free. Safe for leather shoes upper usage. |

| High Elastic Recovery | Maintains structural integrity for sport shoes upper during 1,000,000+ bending cycles. |

| Hydrolysis Resistance | Polyether-grade ensures superior resistance; prevents delamination for tpu film laminate. |

Comparative Advantages: TPU Film vs. Traditional Glue

| Performance | GREEN TPU Hot Melt Film | Solvent-Based Adhesives |

|---|---|---|

| Environmental Impact | Certified Low VOC & non-toxic. | High VOCs and toxic waste. |

| Bond Uniformity | Consistent thickness for sport shoes upper. | Uneven application, risk of seepage. |

| Processing | Instant heat-activated bonding (Fast). | Requires long curing cycles. |

Durable manufacturer tpu film Reliability

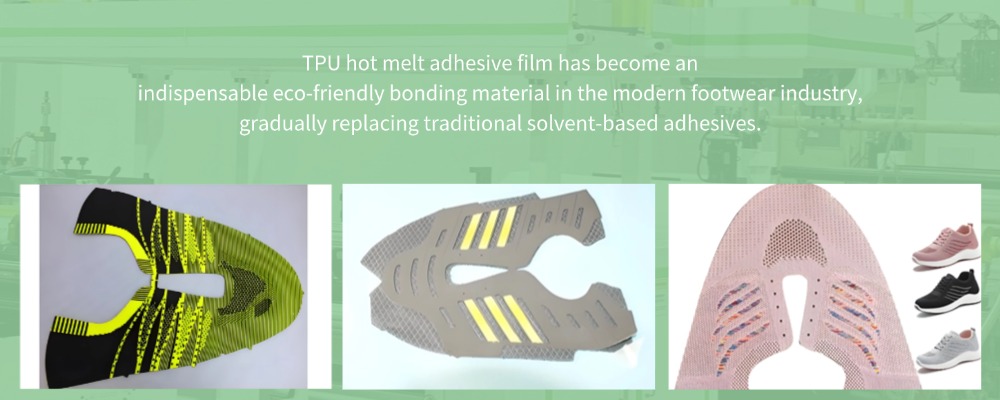

TPU hot melt adhesive film is used in shoe material manufacturing

Why Partner with Our TPU Film for Shoes Supplier?

FAQ: TPU Film for Shoes & Factory Capabilities

Q: Are you a trading company or a tpu film for shoes factory?

A: We are an integrated industry and trade factory specializing in high-strength leather shoes upper tpu hot melt film. Learn more about our factory.

Q: Can you customize tpu film for sport shoes upper?

A: Yes, we accept full OEM/ODM customization to meet your specific technical requirements as a tpu film for shoes supplier.

Q: Do you provide samples of high quality tpu film hot melt film?

A: Yes, we provide free samples (A4 size or trial rolls) for project validation. You only need to cover the shipping cost.