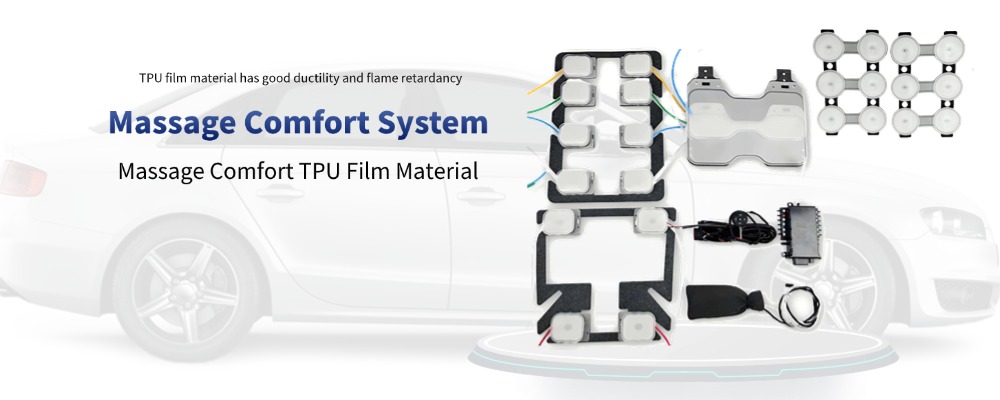

High-Strength TPU Film for Car Seat Massage Airbags | OEM Factory Direct Supply

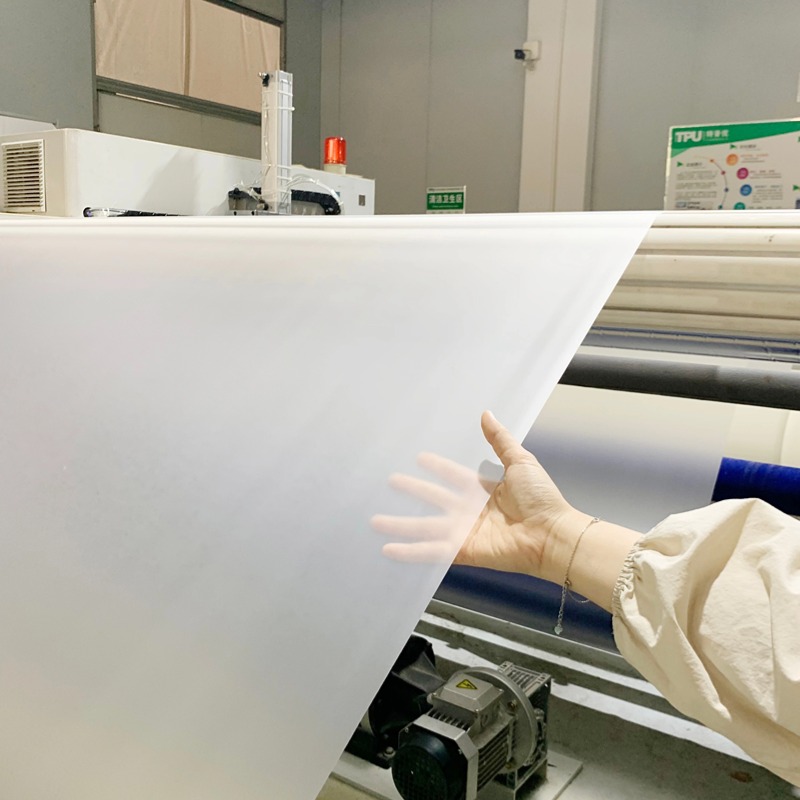

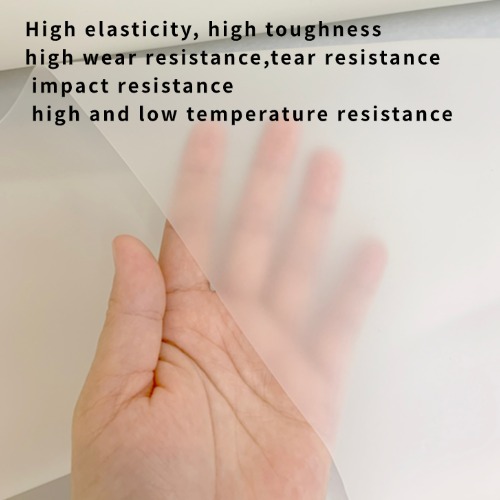

High-performance TPU film is engineered for automotive massage airbags and pneumatic systems. Delivering hermetic airtight sealing and high strength, it meets IATF 16949 standards for OEM durability. This fatigue-resistant material ensures long-term reliability for Tier 1 comfort system applications.

- Order (minimum order quantity): 1000KG

- Payment: Wire transfer, credit card

- Material type: TPU film

- Shore Hardness: 80A-98A (Customizable)

- Thickness Range: 0.1-0.6mm

- Tensile strength: 40 MPa or higher

- Elongation at break: 600% or more

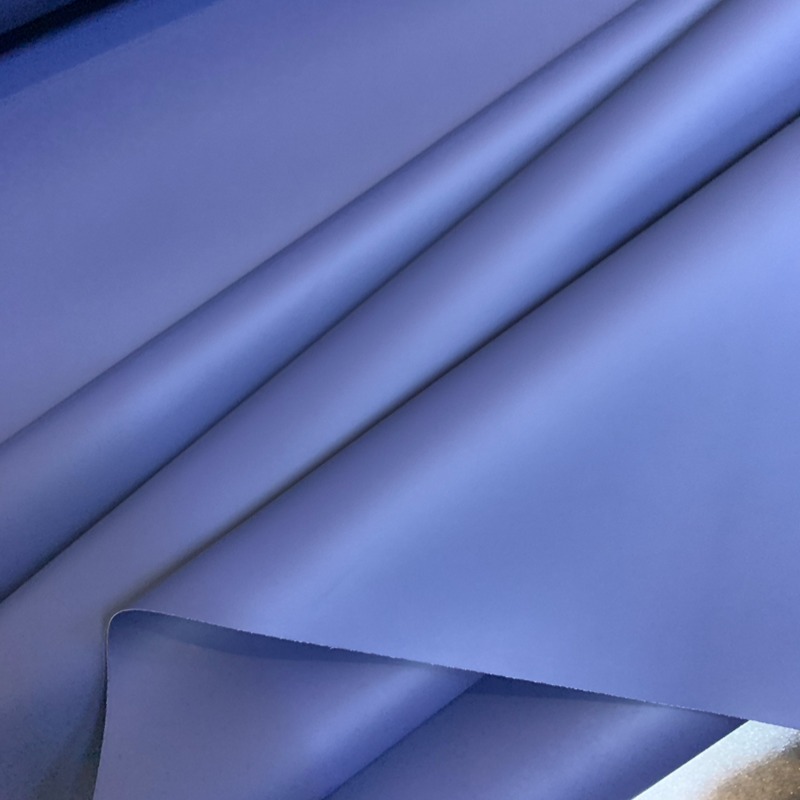

- Color: Transparent/Semi-Transparent (Custom Colors Optional)

- Roll specifications: width 1.37 meters (custom lengths and widths available)

- Certifications: RoHS, REACH, Flame Retardant GB 8410-2006 ISO/IATF16949 Automotive Standards

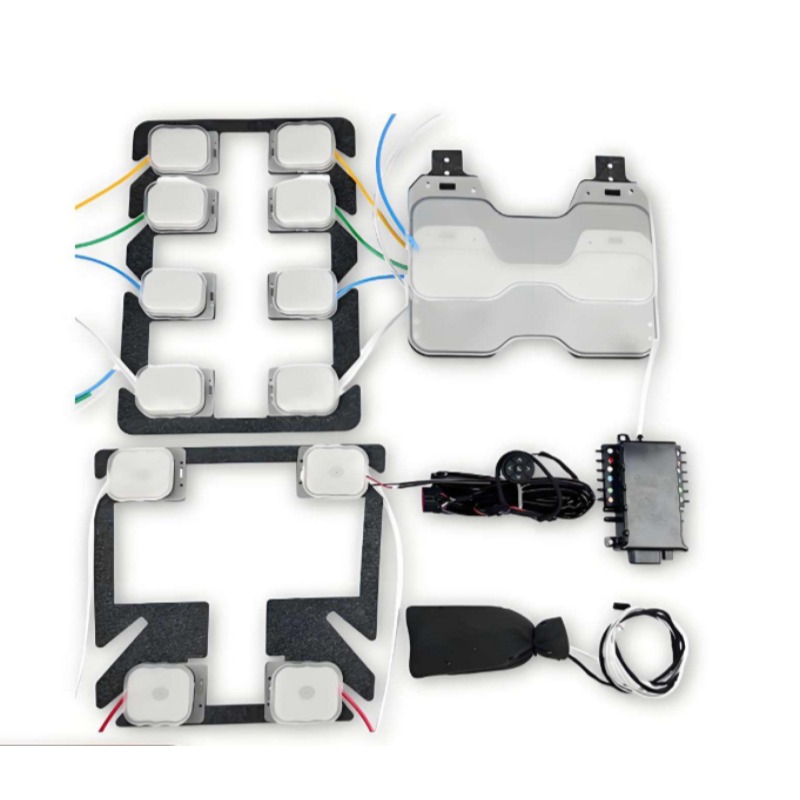

Product Application & Engineering Value

Our high-performance TPU film is engineered specifically for automotive seat massage airbags, pneumatic lumbar support, and active side bolsters. As a critical component in modern Smart Seat Systems, it delivers superior comfort, reliability, and durability for OEMs and Tier 1 suppliers:

🧘 Massage Comfort

Seamlessly adapts to body contours for personalized support. High-rebound material enables rapid response for dynamic massage patterns (Wave, Pulse) without the harsh "plastic" feel.

💺 Pneumatic Lumbar Support

Designed to withstand high sustained pressure. Provides stable, long-term lower back support for drivers during long-distance travel without air leakage.

🏎️ Active Side Bolsters

Fast inflation response for dynamic driving scenarios. The film's high tensile strength ensures the side wings hold the driver firmly during high-speed cornering.

🔒 Precise Pressure Control

Ultra-low gas permeability ensures stable air pressure maintenance over thousands of inflation cycles, crucial for closed-loop pneumatic control systems.

🔇 Quiet Operation (NVH)

Optimized TPU formulation with matte texture reduces friction noise (squeaking) between the bladder and foam during deployment, critical for luxury vehicle acoustics.

💪 Vibration Resistance

High fatigue tolerance prevents material degradation under continuous seat vibration and load changes (Tested over 50,000 dynamic cycles).

🔥 Flame & Halogen Free

Meets FMVSS 302 & GB 8410 standards. Halogen-Free composition ensures safety for seat electronics integration.

View Fire Safety Report →

🌿 Low Fogging & VOC

Fogging Value >92% verified by SGS Report. Low VOC emissions ensure clean cabin air and prevent window residue.

🛡️ Hygiene & Antibacterial

Engineered for health. Achieves >99.9% antibacterial rate against E. coli & S. aureus. Ideal for shared mobility.

View Antibacterial Report →

📦 Safe Logistics

Certified Non-Dangerous Goods for safe transport. Includes Logistics Safety Report to ensure smooth global customs clearance.

Technical Specifications & Advantages

A high-strength, ultra-extensible TPU film specifically designed for automotive massage seat airbags. It provides precise, point-to-point pressure application while avoiding the “squeezing sensation” of traditional airbags.

| Key Feature | OEM Benefit |

|---|---|

| Massage Comfort | Improves comfort by >30% due to ergonomic material flexibility. |

| Durability | Maintains elasticity and shape even after tens of thousands of fatigue cycles. |

| Customizable Specs | Thickness from 0.1mm to 0.6mm. Matte/Glossy finishes available. |

| Safety Standards | Halogen-free, meeting strict emission requirements for luxury vehicles. |

Material Science: Polyether vs. Polyester TPU

Selecting the right TPU chemistry is crucial for seat longevity. We offer both types based on your specific environmental requirements:

| Type | Key Characteristic | Recommended Application |

|---|---|---|

| Polyether TPU | Excellent Hydrolysis Resistance & Microbial Resistance. | Convertible cars, humid climates, or seats exposed to moisture. |

| Polyester TPU | Superior Oil Resistance & Abrasion Strength. | Standard interior enclosed seats, areas with high mechanical friction. |

Processing Guidelines for Manufacturers

High-Frequency (HF) Welding:

Our TPU films are optimized for HF welding. The molecular structure responds instantly to RF energy, creating a hermetic seam that is as strong as the base material, ensuring airtight performance for airbags.

Thermoforming:

Excellent deep-draw capability allows for the creation of complex 3D bladder shapes without significant thinning at the corners.

Adhesion:

Can be easily laminated to fabrics (Nylon, Polyester) or foams to create composite seat structures.

Why Partner with GREEN TPU?

We are not just a supplier; we are your strategic partner in automotive material innovation. From raw material sourcing to final export, our Source Factory ensures quality, compliance, and stability.

FAQ

Q: Are you a trading company or a manufacturer?

A: We are an integrated industry and trade company specializing in the manufacture and export of TPU film materials for over 15 years. Learn more about our factory.

Q: Can we customize performance, size, and color?

A: Yes, we accept full OEM/ODM customization to meet your specific technical requirements.

Q: Do you provide sample services?

A: Yes, we provide free samples (A4 size or trial rolls) for project validation. You only need to cover the shipping cost.