TPU Film for Car Seat Ventilation Bags | Flame-Retardant & Low VOC | Premium Choice for Automotive OEMs

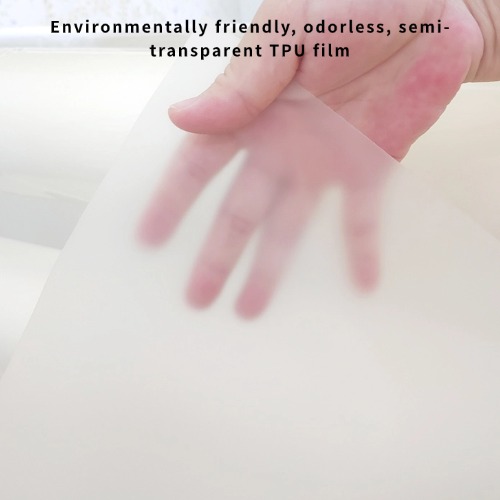

Durable, flame-retardant TPU film designed for car seat ventilation bags. Eco-friendly, odorless, and flexible material that meets OEM requirements, ensuring long-lasting performance, safety, and comfort in automotive interiors.

- Order (minimum order quantity): 1000KG

- Payment: Wire transfer, credit card

- Material type: TPU film

- Shore Hardness: 85A-95A (Customizable)

- Thickness Range: 0.1-0.6mm

- Tensile strength: 40 MPa or higher

- Elongation at break: 600% or more

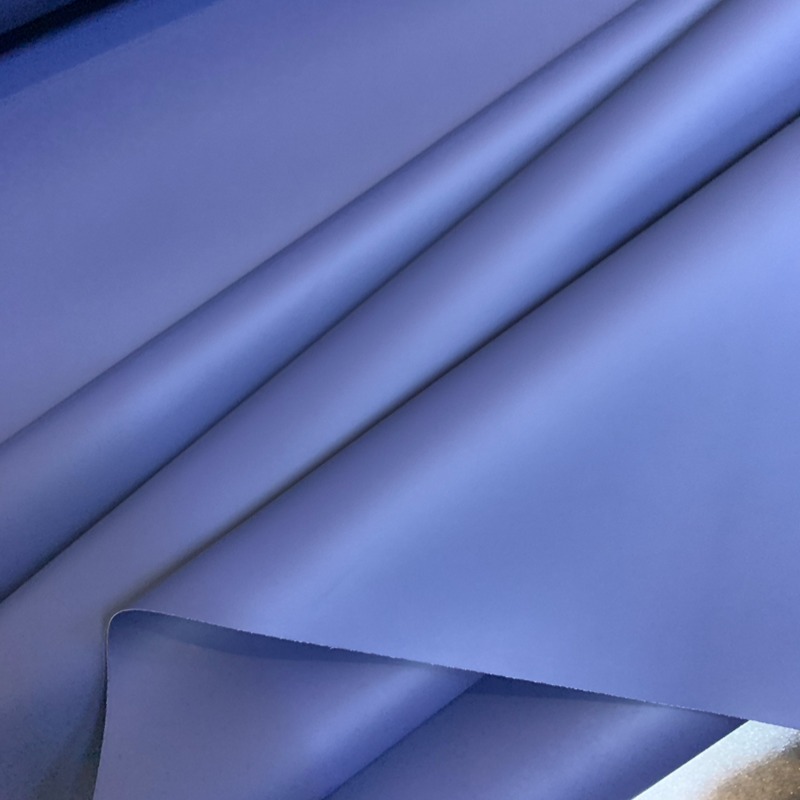

- Color: Transparent/Semi-Transparent (Custom Colors Optional)

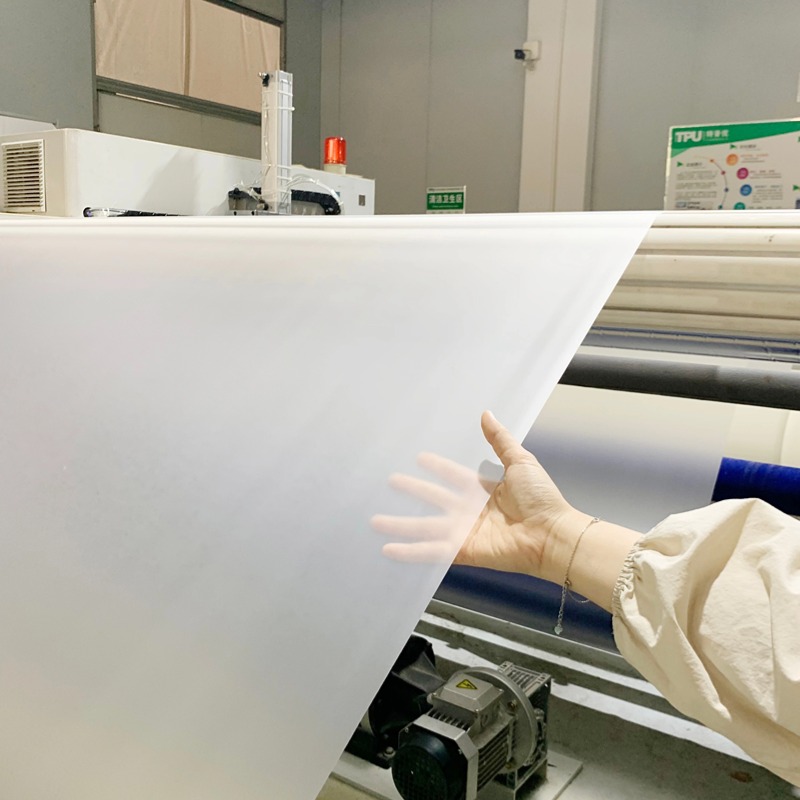

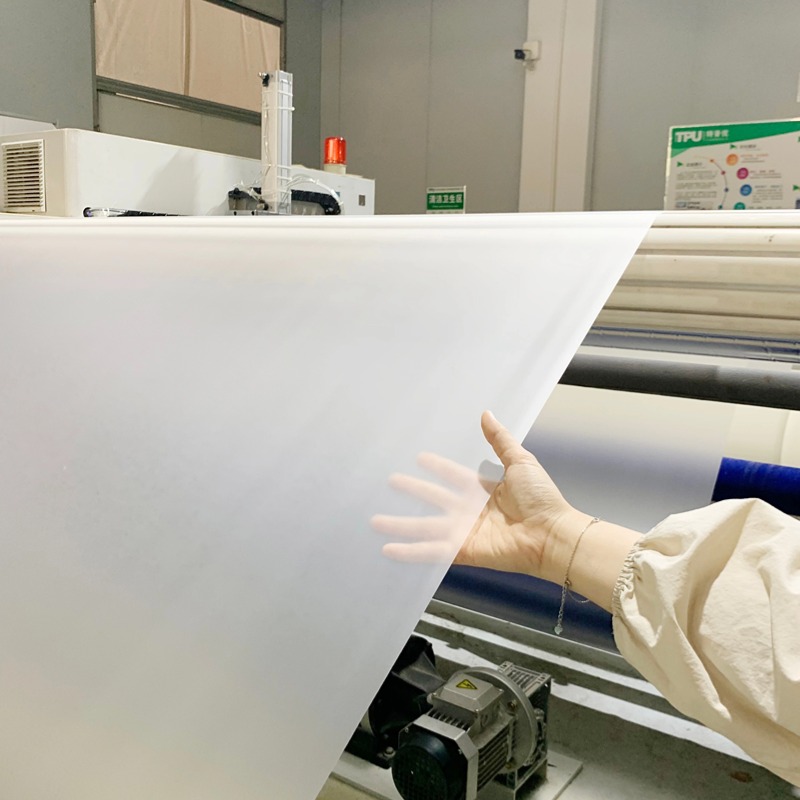

- Roll specifications: width 1.37 meters (custom lengths and widths available)

- Certifications: ISO 9001, RoHS, REACH, SGS Fogging Report

- Flammability: Pass FMVSS 302 / GB 8410

Product Application & Engineering Value

Our high-performance TPU film is specifically engineered for car seat ventilation bags, pneumatic massage bladders, and active bolsters. As a critical component in modern Smart Seat Systems, our material offers Tier 1 suppliers distinct advantages:

🔥 Flame-Retardant & Safe

Engineered to meet GB 8410-2006 and FMVSS 302 automotive flammability standards. The material is self-extinguishing to ensure passenger safety.

View Test Report →

💪 High Fatigue Resistance

Maintains structural integrity under 50,000+ inflation/deflation cycles. Excellent tear resistance against internal seat mechanical friction.

🌿 Low VOC & Eco-Friendly

Fully compliant with RoHS and REACH. Low VOC emissions ensure clean cabin air and prevent window fogging.

🍃 Antibacterial & Odorless

Available with antibacterial properties (>99.9%). Free from plasticizers, preventing any chemical smell transfer.

Why This Film is Essential for Smart Seats

Modern Intelligent Seat Systems require materials that go beyond basic durability. We address the core engineering challenges of pneumatic comfort:

1. Superior Airtightness

Challenge: Air leaks cause pumps to overwork.

Solution: Our TPU boasts extremely low gas permeability, maintaining stable pressure for consistent massage intensity.

2. NVH Optimization (Quiet)

Challenge: "Squeaking" noise in quiet EV cabins.

Solution: Specialized matte surface treatment reduces friction noise between the airbag and seat foam.

3. Precision Thickness

Challenge: Uneven inflation leading to rupture.

Solution: Online Thickness Gauge monitoring ensures ±0.01mm tolerance for uniform balloon expansion.

Technical Specifications & Advantages

| Feature | Benefit for OEMs |

|---|---|

| Customizable Specs | Thickness ranges from 0.1mm to 0.6mm. Available in Matte (Low Noise) or Glossy finishes based on assembly needs. |

| Processing Efficiency | Optimized for High-Frequency (HF) Welding. Creates hermetic seals instantly, improving production yield rates compared to PVC. |

| Flexible Fabrication | Easy to thermoform into complex air channels. The film remains soft and pliable even at low temperatures (-30°C). |

Why Partner with GREEN TPU?

We are not just a supplier; we are your strategic partner in automotive material innovation. From raw material sourcing to final export, our Source Factory ensures quality, compliance, and stability.