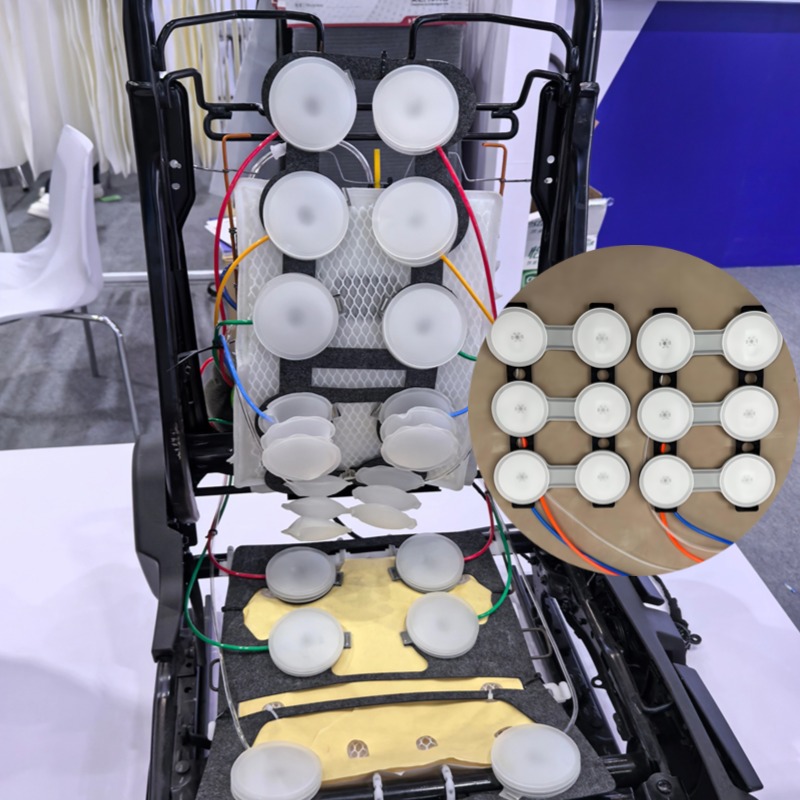

Advancing Seat Comfort: TPU Film Solutions for Massage, Ventilation & Lumbar Support

High-performance TPU films for automotive massage airbags & lumbar support. Low noise, high airtightness & fatigue resistant. REACH/RoHS compliant.

Introduction

In the pursuit of the ultimate driving experience, the vehicle cabin is evolving into a "Third Space." Intelligent seat systems—featuring pneumatic massage, active ventilation, and dynamic lumbar support—are now standard in mid-to-high-end vehicles. The performance of these systems relies heavily on the material quality of the air bladders.

As a specialized manufacturer, GREEN TPU provides high-elasticity, high-airtightness TPU film materials specifically designed for automotive smart seat systems. We help Tier 1 seat manufacturers enhance comfort, reduce noise, and ensure reliability over the vehicle's lifecycle.

Why Material Selection Defines Smart Seat Performance

The transition from mechanical to pneumatic support systems requires materials that can withstand constant movement without failure. Here is how our TPU film addresses critical engineering challenges:

1. Superior Airtightness & Pressure Stability

Pain Point: Minor air leaks cause frequent pump cycling, increasing energy consumption and wear.

Our Solution: Our TPU film boasts extremely low gas permeability. It maintains stable air pressure, ensuring consistent massage intensity without overworking the inflation system.

2. Exceptional Fatigue Resistance (50,000+ Cycles)

Pain Point: High-frequency inflation cycles lead to stress-cracking and material aging in ordinary plastics.

Our Solution: Engineered for durability, our films feature exceptional elastic recovery and tear resistance. Lab tested to maintain integrity after 50,000+ dynamic cycles.

3. Precision Thickness for Safety

Pain Point: Uneven thickness creates "weak spots" leading to balloon rupture under passenger weight.

Our Solution: Utilizing advanced cast film technology with Online Thickness Gauge monitoring, we maintain thickness tolerances within ±0.01mm, guaranteeing uniform inflation safety.

4. Eco-Friendly & High-Efficiency Welding

Pain Point: Poor weldability leads to slow production and leaking seams.

Our Solution: 100% plasticizer-free and optimized for High-Frequency (HF) welding. Forms strong, hermetic seals instantly for high yield rates.

Application Scenarios: Critical Seat Components

Our TPU films are tailored for specific pneumatic functions within the seat structure:

| Seat Component | Functional Requirement & Solution |

|---|---|

| Seat Massage Airbags | Requirement: Rapid Response & Durability. Solution: High-rebound TPU enables quick inflation/deflation sequences for dynamic massage patterns (Wave, Pulse, Knead). |

| Seat Ventilation Bags | Requirement: Airflow & Structure. Solution: Rigid enough to maintain air channels when sat upon, yet flexible enough not to be felt by the passenger. |

| Lumbar Support Bladders | Requirement: High Load Bearing. Solution: High-tensile strength films that support the driver's lower back weight for hours without deforming. |

| Side Wing Support Airbags | Requirement: Dynamic Lateral Support. Solution: Fast-acting inflation to hold the driver in place during high-speed cornering (Active Bolsters). |

Seat Massage Airbags

Seat Ventilation Airbags

Lumbar Support

Side Wing Support

Technical Deep Dive: NVH & Safety Standards

For automotive OEMs, comfort is not just about feeling; it is about sound and safety. We have optimized our TPU formulation to meet strict automotive standards.

1. Quiet Operation (NVH Optimization)

The Challenge: In a quiet electric vehicle (EV) cabin, the "crinkling" or "squeaking" sound of airbag friction is unacceptable.

GREEN TPU Innovation: We utilize a specialized soft-touch matte surface technology. This reduces the coefficient of friction between the airbag and the seat foam, ensuring silent operation.

2. Flame Retardancy & Safety

Passes FMVSS 302 and GB 8410-2006 requirements. Material is self-extinguishing once the ignition source is removed.

3. Low VOC & Odor Control

Odorless: Grade ≤ 3.0 (VDA 270). Fogging: >90% consistency to prevent windshield residue.

Product Series: Tailored for Specific Functions

We offer distinct TPU grades optimized for different smart seat subsystems:

| TPU Series | Key Features & Benefits |

|---|---|

| Massage Series (High Elasticity) | Ergonomic Flexibility: Seamlessly adapts to body contours for personalized support. Vibration Resistance: High fatigue tolerance prevents material degradation under continuous vehicle vibration. |

| Ventilation Series (Structural) | Space-Saving Design: Thin yet robust structure allows compact integration into slim seat designs. Easy Forming: Can be thermoformed into complex air-channel shapes without thinning. |

Conclusion: Secure Your Supply Chain

In the competitive automotive landscape, the stability of your upstream supply chain is just as critical as product innovation. GREEN TPU offers scalable production capacity and consistent ISO/IATF quality control.

Partner with us to ensure your smart seat systems are built on the most reliable, high-performance foundation available.

Contact Our Sales Team for Supplier Cooperation