What is TPU Film? A Comprehensive Guide to Properties, Manufacturing, and Applications

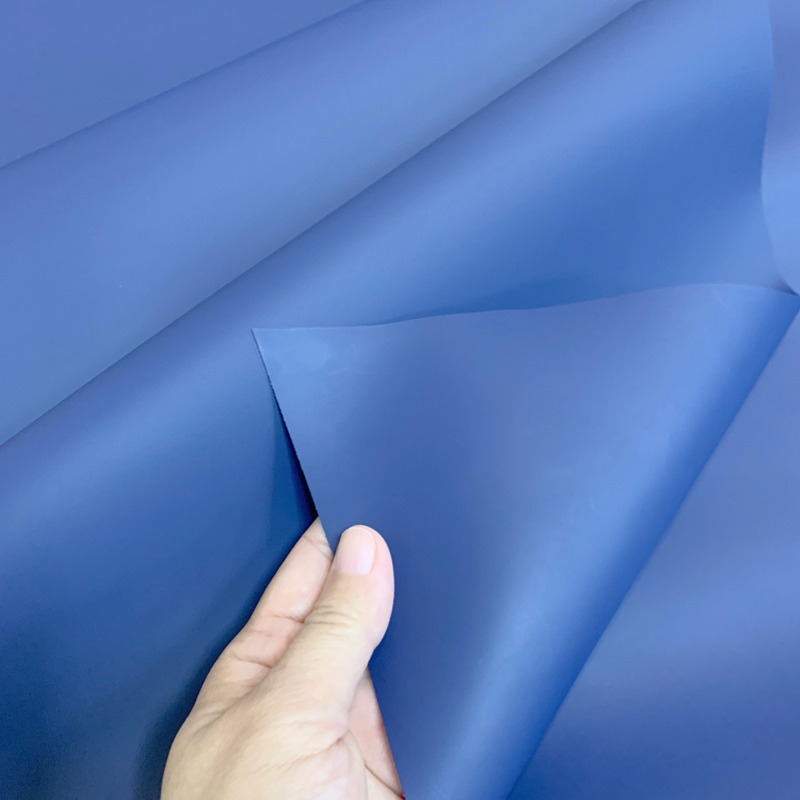

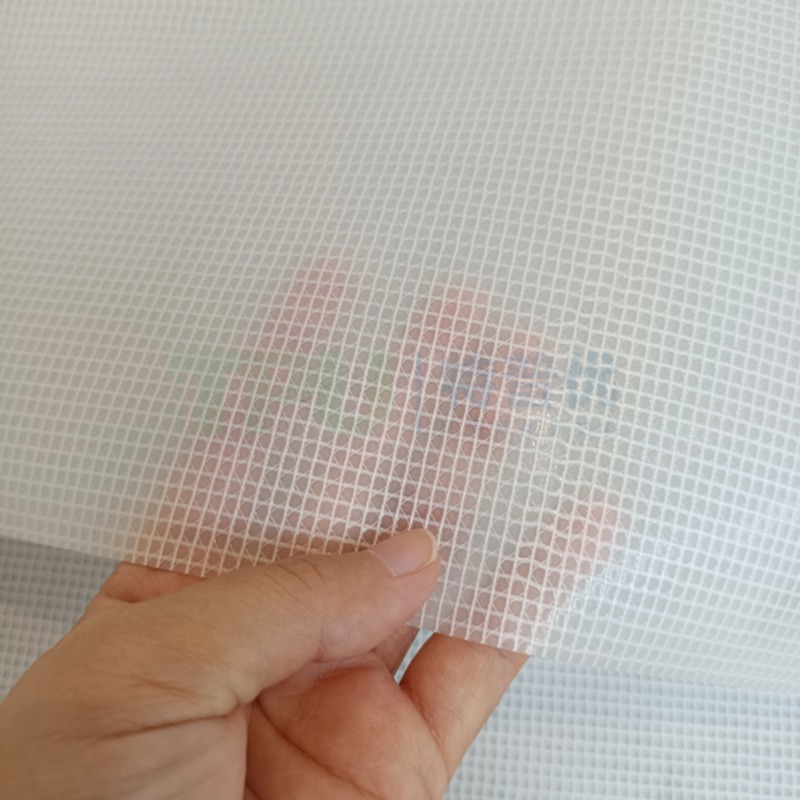

TPU Film (full name: thermoplastic polyurethane film) is a high-performance film material made primarily from thermoplastic polyurethane (TPU). It combines the high elasticity of rubber with the processability of thermoplastic plastics, exhibiting excellent elasticity, transparency, oil resistance, grease resistance, and abrasion resistance. Depending on the application requirements, TPU film can be prepared using molding processes such as casting, extrusion, or blow molding, and is widely used in footwear, clothing, electronic products, automotive interiors, and medical devices.

Main Manufacturing Processes

🏗️ Casting

TPU raw material is heated and melted through an extruder, then uniformly cast onto cooling rollers to form a film. This process produces films with uniform thickness, high transparency, and a smooth surface, suitable for applications requiring high transparency or high precision.

🎈 Blown Film

Molten TPU material is blown into a film using airflow, then cooled, shaped, and wound up. This process is suitable for producing films with high flexibility, thinness, and excellent toughness, commonly used in clothing, packaging, and protective applications.

🚜 Calendering

Molten TPU resin is repeatedly calendered using a multi-roll calendering machine to produce TPU films with greater thickness and stable mechanical properties. This process is commonly used in applications requiring high strength, such as automotive interiors, industrial protective materials, and shoe composites.

Key Properties of TPU Film

TPU film offers a unique combination of elasticity, toughness, and versatility, making it one of the most popular high-performance materials in modern manufacturing. Its balanced physical and chemical properties allow it to perform well under a wide range of environmental conditions. Below are the key characteristics of TPU film:

🏃 Excellent Elasticity and Flexibility

TPU film maintains outstanding flexibility even at low temperatures. It can stretch and recover without deformation, providing superior comfort for TPU film applications in footwear and wearables.✨ 95% High Transparency & Aesthetics

Thanks to its excellent optical clarity, High-transparency TPU film is widely used in protective covers, transparent labels, and consumer electronics.🛡️ Superior Abrasion Resistance

Compared with polymers like PVC and EVA, our Functional TPU film demonstrates much higher resistance to wear, scratches, and surface damage.🧪 Chemical and Oil Resistance

Performs well in contact with oils and chemicals, making it suitable for automotive interiors and specialized TPU composite fabric.🌿 Eco-Friendly & Safety Compliance

As a solvent-free material, it meets REACH & RoHS, including Low VOC & Halogen-Free options.🔗 Excellent Adhesion

Bonds easily with textiles and leather. Explore our TPU hot melt adhesive film for high-precision composite bonding.📏 Wide Range of Hardness and Thickness Options

Depending on the formulation and processing method, TPU films can be customized in hardness and thickness to meet specific functional or aesthetic requirements.Applications of TPU Film

TPU film is used in a wide range of industries. Below are some of the most common applications:

Footwear and Apparel

Automotive Industry

Medical and Healthcare Products

Outdoor and Sports Equipment

Industrial Laminates and Composites

Packaging and Decorative Applications

TPU Film vs Other Materials

In many applications, TPU film is compared with other common materials such as PVC, PU, and EVA. While each material has its own advantages, TPU film offers a balanced performance that makes it an increasingly popular choice in advanced manufacturing. Below is a general comparison:

TPU Film vs PVC Film

PVC film is cost-effective and easy to process, but it contains plasticizers and chlorine, which can cause environmental and aging issues. TPU film, on the other hand, is non-toxic, odorless, and free from halogens. It provides better elasticity, abrasion resistance, and weather stability, making it more suitable for high-end and eco-friendly products. Below is a comparison between TPU film and PVC film in key performance aspects:

| TPU Film | PVC Film |

|---|---|

| Elasticity & Flexibility: Excellent elasticity and flexibility, even at low temperatures | Elasticity & Flexibility: Moderate flexibility; becomes brittle in cold conditions |

| Abrasion Resistance: Outstanding; highly resistant to wear and scratches | Abrasion Resistance: Poor; prone to surface damage and wear over time |

| Chemical & Oil Resistance: Excellent; resistant to oils, grease, and chemicals | Chemical & Oil Resistance: Poor; easily affected by oils and solvents |

| Transparency & Appearance: High clarity; remains transparent and stable over time | Transparency & Appearance: Good clarity, but tends to yellow or harden with aging |

| Weather & UV Resistance: Excellent; stable against UV light and temperature changes | Weather & UV Resistance: Poor; easily degraded by UV exposure and heat |

| Environmental Impact: Non-toxic, Halogen-free, and recyclable; meets Low VOC standards. | Environmental Impact: Contains chlorine and plasticizers; not environmentally friendly |

| Processing Methods: Suitable for casting, extrusion, lamination, and heat bonding | Processing Methods: Easy to process and low cost, but limited in performance |

| Typical Applications: High-end footwear, automotive interiors, electronics, medical and outdoor products | Typical Applications: Low-cost packaging, raincoats, inflatable toys, and decorative films |

TPU Film vs PU Film

PU films have a soft touch and a smooth appearance, and are commonly used in clothing, interior decoration, and coatings. However, they are sensitive to moisture and UV radiation, and their durability under harsh conditions is limited. TPU films, on the other hand, possess excellent elasticity, mechanical strength, and abrasion resistance. They maintain their performance at varying temperatures and can be thermoformed, welded, and recycled, making them ideal for high-performance and sustainable applications. Below is a comparison between TPU film and PU film in key performance aspects:

| TPU Film | PU Film |

|---|---|

| Elasticity & Flexibility: Excellent elasticity and flexibility; retains rebound and shape over time | Elasticity & Flexibility: Good softness and hand feel; may lose elasticity faster under stress |

| Abrasion Resistance: Outstanding; highly resistant to abrasion, tearing, and surface wear | Abrasion Resistance: Moderate; suitable for general use but less durable than TPU |

| Chemical & Oil Resistance: Excellent; strong resistance to oils, greases, and many chemicals | Chemical & Oil Resistance: Limited; susceptible to certain oils and solvents |

| Hygiene & Safety: Antibacterial properties and Flame Retardant options available. | Hygiene & Safety: Standard PU films often lack specialized barrier treatments. |

| Weather & UV Resistance: Excellent outdoor stability and UV resistance | Weather & UV Resistance: Moderate; can degrade faster under UV or humidity |

| Environmental Impact: Halogen-free, recyclable, and solvent-free options available | Environmental Impact: Some formulations use solvents; less eco-friendly |

| Processing Methods: Suitable for extrusion, casting, lamination, and heat bonding | Processing Methods: Usually produced by solvent or water-based coating; requires curing |

| Typical Applications: High-end footwear, automotive interiors, electronics protection, outdoor and medical products | Typical Applications: Fashion leather, upholstery, coatings, decorative films |

TPU Film vs EVA Film

EVA film is lightweight, flexible, and offers good transparency, often used in solar encapsulation, packaging, and footwear materials. However, it has lower mechanical strength, heat resistance, and chemical stability compared to TPU film. TPU film, on the other hand, provides higher durability, elasticity, and resistance to oil and abrasion. It also performs better in outdoor and high-temperature environments, making it more suitable for demanding industrial and consumer applications. Below is a comparison between TPU film and EVA film in key performance aspects:

| TPU Film | EVA Film |

|---|---|

| Elasticity & Flexibility: Excellent elasticity and flexibility; retains shape even under stress | Elasticity & Flexibility: Soft and flexible but less elastic and resilient than TPU |

| Abrasion Resistance: Outstanding; highly resistant to surface wear and mechanical stress | Abrasion Resistance: Fair; less durable and more prone to surface wear |

| Automotive Standards: Passed Automotive Fogging and Low Emission tests. | Automotive Standards: Weak chemical stability; fails strict outgassing requirements. |

| Transparency & Appearance: High clarity and stable transparency over time | Transparency & Appearance: Good transparency and gloss, but may haze with aging |

| Weather & UV Resistance: Excellent; performs well under UV and outdoor exposure | Weather & UV Resistance: Moderate; can degrade faster under UV and heat |

| Environmental Impact: Non-toxic, halogen-free, and recyclable; eco-friendly choice | Environmental Impact: Non-toxic, but lower durability shortens lifespan |

| Processing Methods: Suitable for extrusion, casting, lamination, and vacuum forming | Processing Methods: Easy to process via extrusion; lower heat resistance limits use |

| Typical Applications: High-end footwear, outdoor gear, automotive interiors, medical and protective films | Typical Applications: Solar encapsulation, packaging, foam products |

Summary

Overall, TPU film offers an exceptional balance of flexibility, strength, and environmental responsibility. It combines the elasticity of rubber with the processability of thermoplastics, providing a durable and sustainable alternative to conventional plastic films.

Thanks to its superior performance and eco-friendly nature, TPU film has become the material of choice for a wide range of high-end and technical applications.

Why choose us?

Reliable Manufacturing · Proven Quality · Global Trust

- 300 tons of raw materials always in stock.

- Advanced, high-efficiency TPU film production equipment.

- Manufacturer-direct supply with fully automated production lines, annual output up to 6,000 tons.

- Certified quality management system: ISO 9001, RoHS, SGS, and more.

Product Overview

We specialize in TPU films and TPU hot melt adhesive films, offering customized solutions that ensure high quality, durability, and safety across medical, automotive, and outdoor sectors.

【View All Products】FAQ

Q: Are you a trading company or a manufacturer?

A: We are an integrated industry and trade company specializing in the manufacture and export of TPU film materials for over 15 years. Learn more about our factory.

Q: Can we customize performance, size, and color?

A: We accept customization of various specifications to match your performance requirements.

Q: Do you provide sample services?

A: We can now provide a certain quantity of free samples for validation. You only need to cover the shipping costs.