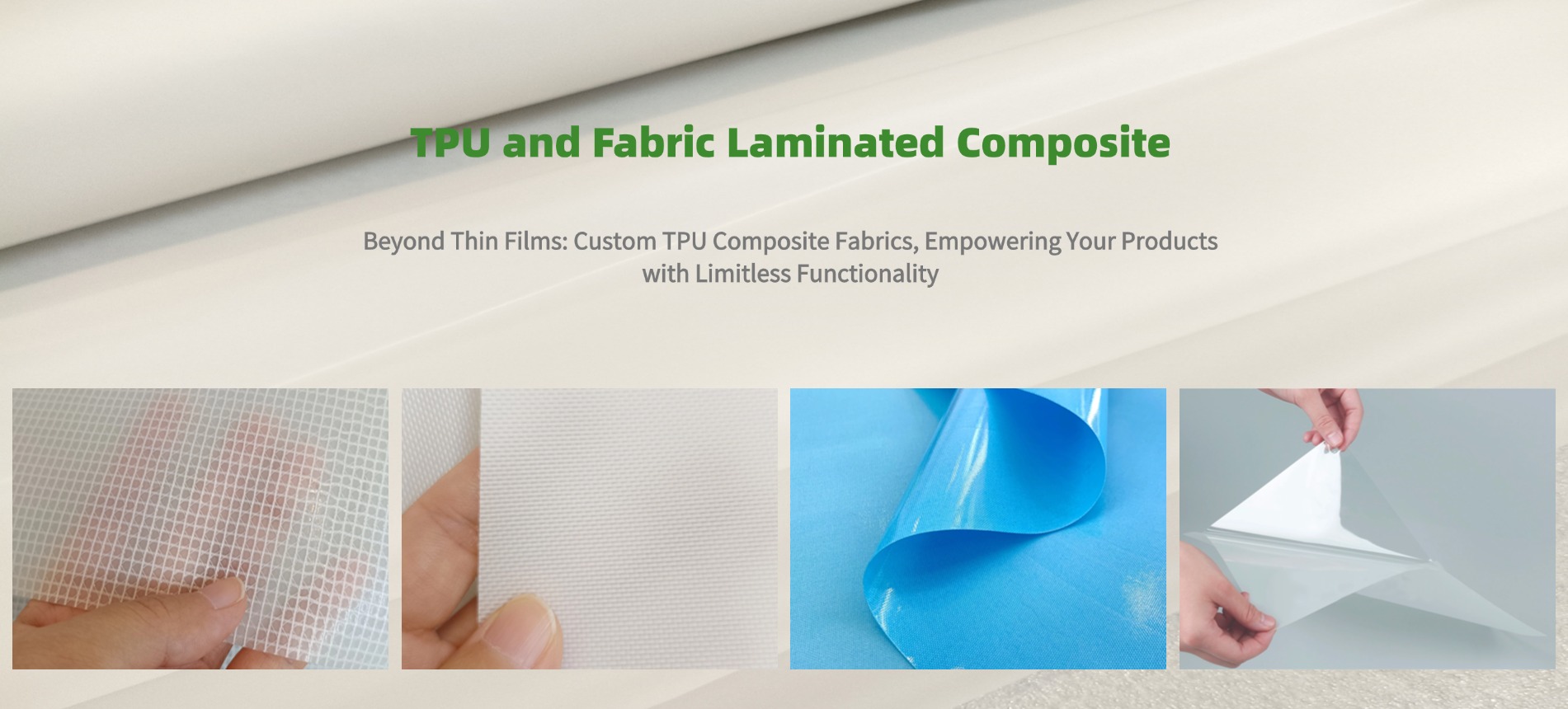

TPU Composite Fabric Customization Experts — TPU & Fabric Laminated Solutions

Customized TPU composite fabrics combining TPU film with mesh, nylon, Oxford or polyester to deliver waterproof, airtight, abrasion-resistant and durable laminated materials for inflatable products, outdoor gear, medical devices and industrial protection.

Introduction

Demand for multifunctional materials is rising across outdoor equipment, inflatable structures, healthcare, and industrial protection. TPU composite fabric—formed by laminating TPU film onto textile substrates—offers a unique combination of structural strength and functional protection. These composites deliver superior elasticity, sealing, durability and environmental compliance, making them ideal for next-generation product designs.

What is TPU Composite Fabric and Why It Matters

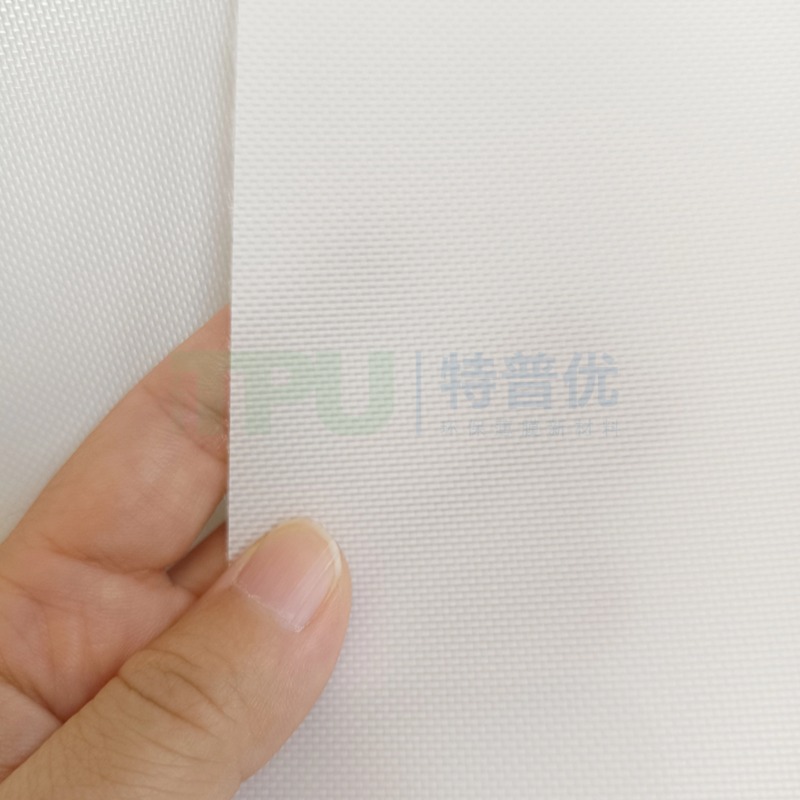

TPU composite fabric is produced by bonding a TPU functional layer to a base fabric substrate. The base fabric provides structural strength and tactile appearance, while the TPU layer provides barrier protection and functional performance.

- Base fabric role: tensile and tear resistance, surface texture, dimensional stability

- TPU layer role: waterproofing and airtight sealing, elasticity, abrasion and aging resistance, heat-sealability

- The resulting composite delivers a balanced material that is both protective and comfortable for end-use products

Application Product Categories

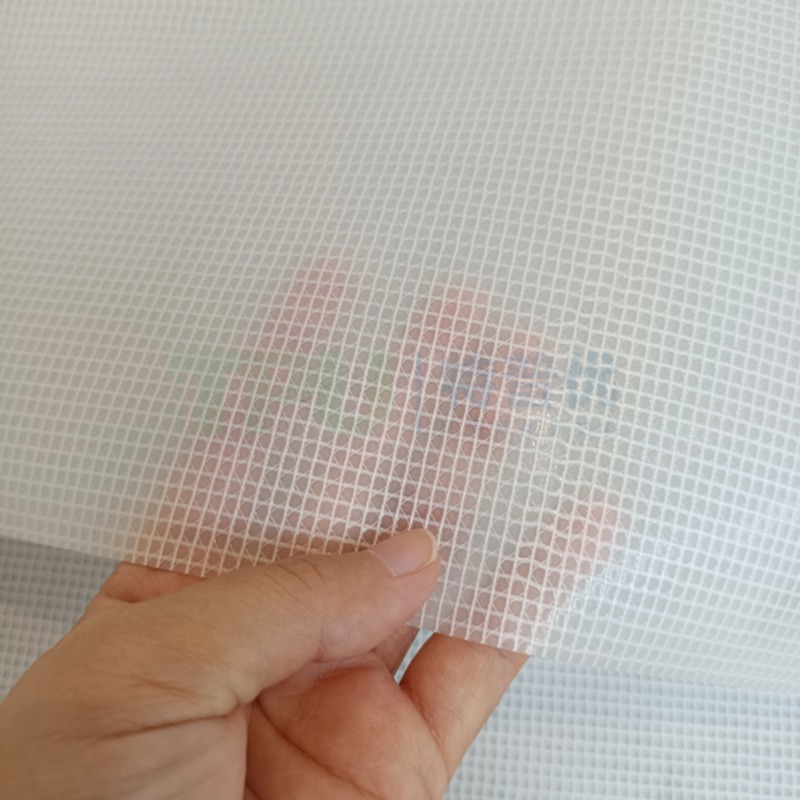

| TPU laminated mesh fabric | ||

| Provides breathability combined with waterproofing and durability for sports gear, flexible structures and ventilation-enabled products. | |

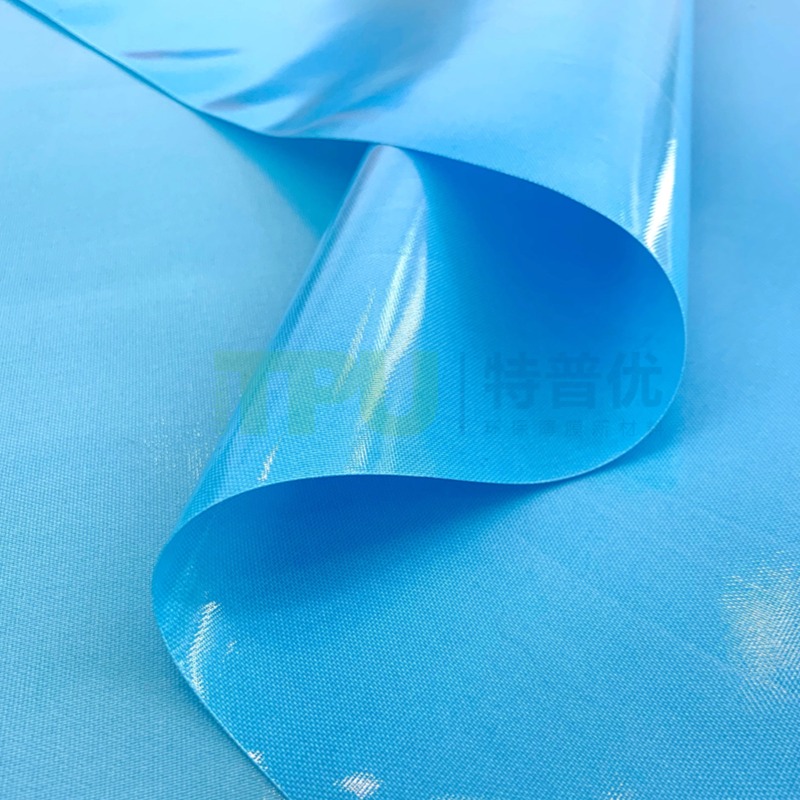

| TPU laminated nylon fabric | ||

| High strength and excellent sealing for inflatable tents, airbags, packrafts and high-load inflatable products. | |

| TPU laminated Oxford cloth fabric | ||

| Enhanced abrasion resistance and toughness for heavy-duty outdoor equipment, luggage, canopies and industrial covers. | |

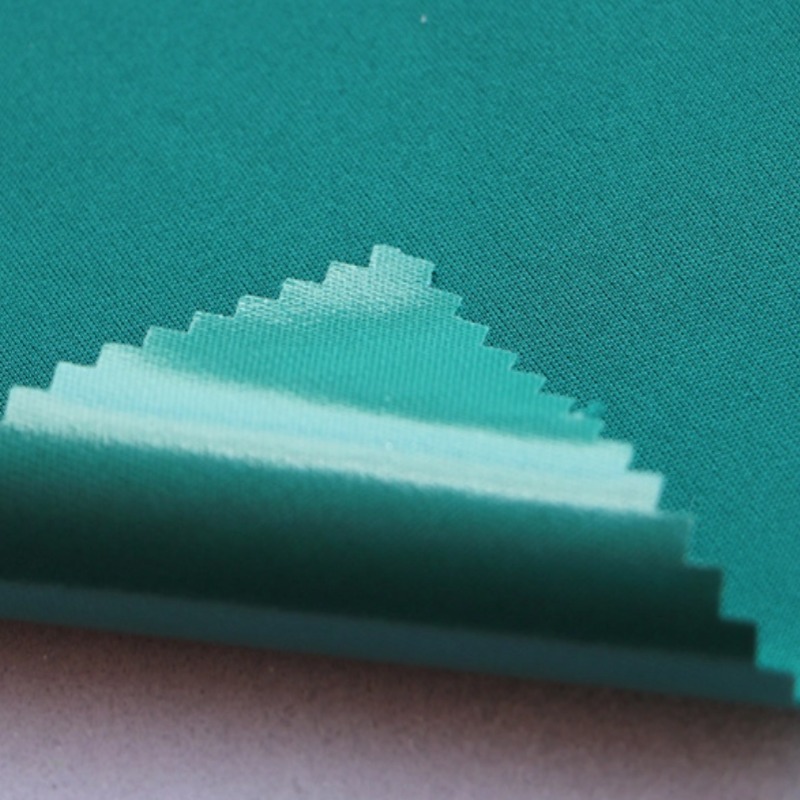

| TPU laminated polyester fabric | ||

| Stable, cost-effective option used in waterproof bags, medical covers, protective garments and general outdoor products. | |

Key Benefits and Core Strengths

- High strength and durability: TPU + fabric synergy delivers superior tear and abrasion resistance compared to single-layer materials.

- Lightweight and soft: Maintains flexibility and comfort while adding robust protection and structure.

- Seamless waterproof sealing: Composite materials weld cleanly—enabling fully sealed products via high-frequency welding without additional tapes.

- Environmental and safety compliance: TPU formulations can be phthalate-free and meet REACH, RoHS, OEKO-TEX® and related standards.

- Customizable performance: Thickness, hardness, color and surface finish can be tuned per application requirements.

Custom Development Process

- Requirements consultation: Evaluate application scenario, waterproof rating, flexibility, weight, aesthetics and budget.

- Base fabric selection: Customer-supplied or supplier-recommended options such as high-strength nylon, Oxford, knitted fabrics or mesh.

- Process determination: Choose coating, hot-melt lamination or multi-layer approaches to meet adhesion and durability targets.

- Sample production and testing: Provide prototypes; perform hydrostatic, peel, thermal, UV and fatigue tests to validate performance.

- Mass production and delivery: Factory-direct manufacturing ensures consistent quality control and reliable lead times.

Technical Advantages & Performance Highlights

| TPU Composite Feature | Benefit for End-Use Products |

|---|---|

| Tensile & tear resistance | Maintains shape and resists puncture or tearing under load—important for inflatables and rugged outdoor gear. |

| Elasticity & flexibility | Allows repeated folding and inflation cycles without cracking, preserves comfort and structural integrity. |

| Heat-sealability | Enables strong, airtight seams with professional welding, reducing long-term leak risk. |

| Environmental durability | UV resistance, hydrolysis resistance and wide temperature tolerance extend outdoor service life. |

Industry Trends & Market Status (2024 Data Summary)

TPU film rapidly penetrated the inflatable product sector during 2020–2024. Market research indicates TPU penetration rose from under 15% in 2020 to approximately 38% in 2024, driven by a compound annual growth rate well above the industry average. This shift is visible as a top-down diffusion: TPU dominates mid-to-high-end inflatable mattresses (over 60% market share) and exceeds 75% application rates in specialized outdoor tents and high-end inflatable boats. These trends indicate that TPU replacing PVC is an ongoing industrial reality rather than a future projection.

Testing, Standards and Quality Assurance

- Air retention and hydrostatic testing: Validate long-term airtight performance under repeated cycles.

- Peel strength and adhesion testing: Ensure TPU-film-to-fabric bond meets application loads.

- Environmental simulation: UV aging, temperature cycling and humidity exposure tests.

- Mechanical testing: Tensile, elongation and abrasion resistance assessments.

- Compliance checks: REACH, RoHS, OEKO-TEX® and applicable ASTM/EN standards for intended markets.

Manufacturing Capabilities and Factory Strength

- Multiple production lines for coating and lamination to support sample and volume orders

- Advanced hot-melt lamination and solvent-free coating options for medical-grade and eco-sensitive applications

- Dedicated R&D and engineering teams for material formulation and process optimization

- ISO9001-aligned quality management and full traceability from raw materials to finished composite rolls

Typical Use Cases and Application Value

- Inflatable structures: Boats, rescue rafts, airbags and high-load mattresses benefit from airtight strength and weldability.

- Medical & rehabilitation: Pressure-relief mattresses and washable protective clothing gain comfort, hygiene and disinfectability.

- Industrial & military: Flexible liquid storage, inflatable shelters and canopies require chemical and weather resistance.

- Outdoor & consumer: Backpacks, waterproof bags, sleeping systems and glamping products gain durability and premium feel.

Why Choose Customized TPU Composite Fabrics

- Tailored formulations and fabric pairings to meet exact product requirements

- One-stop service from concept, sampling and testing to bulk production

- Proven performance in demanding sectors with repeatable quality

- Support for high-frequency welding and seamless product manufacture

- Ability to meet strict international environmental and safety certifications

Contact & Next Steps

If you have a specific product concept or need material recommendations, request sample development and performance testing to validate fit-for-purpose results. We can recommend base fabrics, tune TPU thickness and hardness, and produce application-ready composite rolls.