Customizable TPU Film Rolls | Multi-Specification & Non-Toxic | Competitive OEM Factory Direct Wholesale

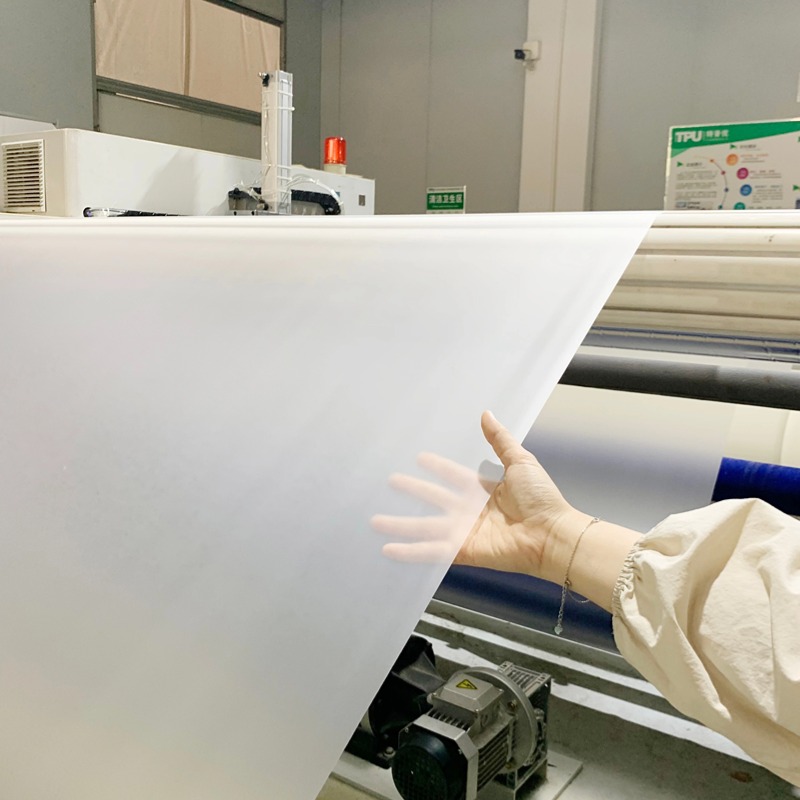

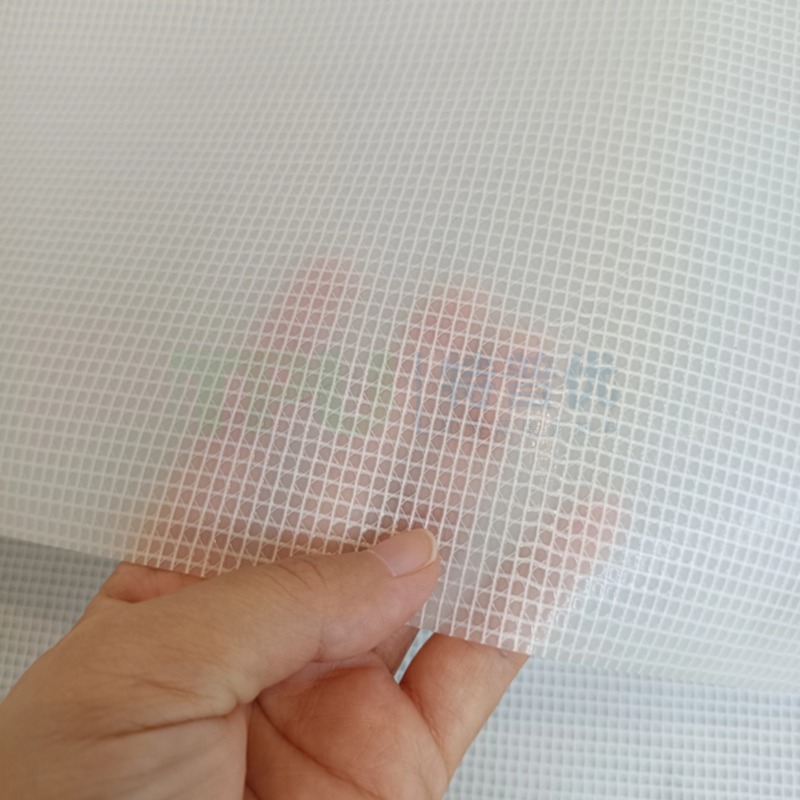

Unlock limitless manufacturing possibilities with GREEN TPU’s Customizable Film Rolls. As a source manufacturer, we offer precise tailoring of width, thickness, hardness, color, and surface finish (Matte/Clear) to match your exact specifications.Engineered for versatility, our films are widely used in automotive interiors, medical devices, high-end apparel, and outdoor gear. Fully certified with RoHS, REACH, and OEKO-TEX, our eco-friendly materials ensure safety and performance for global markets.

- Product Name: Customizable TPU Film Rolls

- Payment: Wire transfer, credit card

- Order (minimum order quantity): 1000KG

- Material System: Polyester (TPU-PE) / Polyether (TPU-ET)

- Thickness Range: 0.02mm – 2.5mm

- Width Specifications: Standard width 1.37 meters (length and width can be customized)

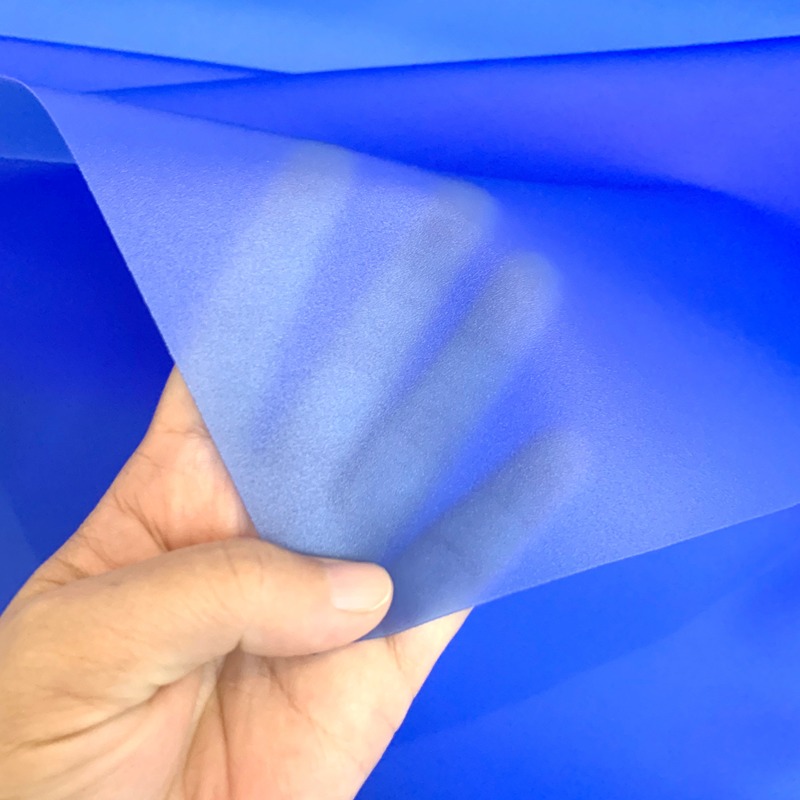

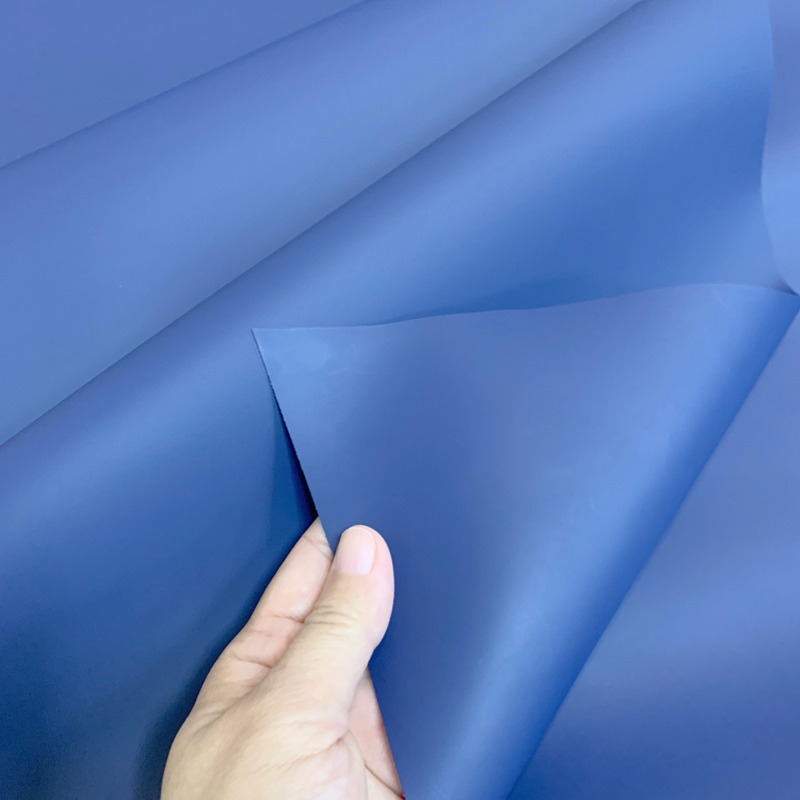

- Appearance & Color: Transparent, Matte, Double-Sided Frosted, Foggy (Customizable Colors)

- Management Standards: ISO 9001:2015, IATF 16949:2016 (Automotive Quality)

- Environmental Certifications: RoHS, REACH, Halogen Free

- Performance Reports: Automotive Fogging, VOC Emission Test, Antibacterial (>99.9%)

- Safety Standards: GB 8410-2006 (Flammability), Logistics Safety Report (Non-Dangerous Goods)

Comprehensive Product Solutions

Our customizable TPU films serve as the foundation for high-performance products across multiple industries. We provide specialized solutions for the following key sectors:

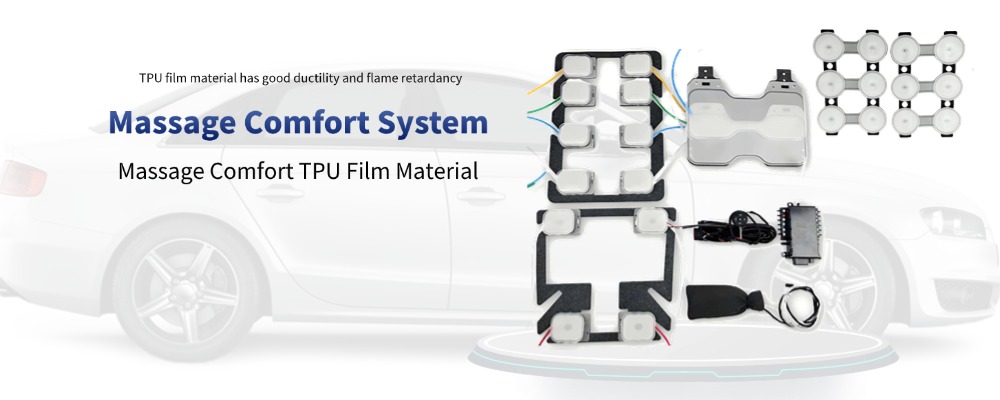

🚗 Automotive Smart Systems

Specs: Low VOC, Flame Retardant, IATF 16949 Certified.

Through our custom TPU film solutions, we meet the precise requirements for automotive pneumatic systems. The specialized matte texture effectively minimizes friction noise (NVH). Customizable thickness directly impacts burst strength and flexibility, ensuring optimal performance for seat massage airbags and lumbar support.

View Automotive Solutions →🏥 Medical & Healthcare

Specs: Bio-compatible, Antibacterial, Non-Toxic.

Through our custom TPU film solutions, we meet the precise requirements for blood pressure monitor airbags and infusion bags. As a safe, non-toxic alternative to PVC, this bio-compatible material is inherently resistant to bacteria and sterilization chemicals, delivering superior tear strength and air-tightness for critical fluid and air management.

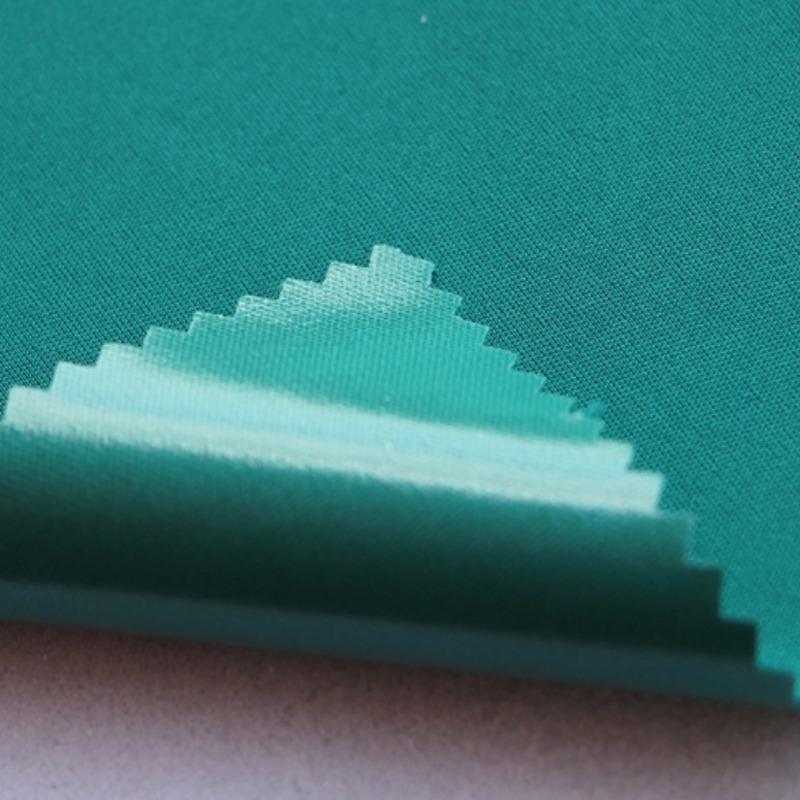

View Medical Solutions →🧥 Textile & Hot Melt Bonding

Specs: High Elasticity, Washable, OEKO-TEX Standard.

Through our custom TPU hot melt film solutions, we meet the precise bonding requirements for seamless underwear, footwear, and waterproof zippers. Eliminating the need for traditional stitching, this solvent-free adhesive ensures superior wash resistance and high elasticity, providing a soft-touch finish that maintains strong adhesion even after repeated laundering.

View Hot Melt Solutions →⛺ Inflatables & Outdoor

Specs: Hydrolysis Resistant, Cold Flex (-40°C).

Through Our customized TPU film solutions are engineered to meet the strict requirements of air mattresses, hydration packs, and tents. These high-strength materials offer superior hydrolysis resistance and remain flexible even at -40°C, providing exceptional abrasion resistance and air-holding capability to ensure lightweight durability in harsh outdoor environments.

View Outdoor Solutions →Technical Specifications (Customizable)

As a professional TPU film manufacturer, the high-quality TPU film rolls we produce can be fully tailored to meet your specific application requirements within the following customization ranges:

| Parameter | Specification Range |

|---|---|

| Material System | Polyester (TPU-PE) / Polyether (TPU-ET) |

| Thickness Range | 0.02mm – 2.5mm (Tolerance ±0.005mm) |

| Shore Hardness | 80A – 98A (Customizable softness) |

| Width Specs | Standard 1.37m (Customizable length & width) |

| Appearance | Transparent (95% Transmittance), Matte, Frosted, Foggy |

| Tensile Strength | 30 MPa (Adjustable based on application) |

| Elongation | 500% (Adjustable based on requirement) |

| Tear Strength | 70–140 kN/m (Low to high tear resistance grades) |

| Temp Range | -40°C to 120°C |

The values listed above represent typical ranges. We strongly recommend contacting our engineering team for a precise Technical Data Sheet (TDS) matching your specific customization needs.

Why Upgrade to TPU? (Material Comparison)

| Performance Metric | GREEN TPU Film | Traditional PVC |

|---|---|---|

| Environmental Safety | 100% Virgin Material, Recyclable, Low VOC. | Difficult to recycle, high chemical odor. |

| Durability | High abrasion & Hydrolysis Resistance. | Prone to yellowing and hardening over time. |

| Cold Resistance | Remains flexible at -40°C. | Becomes brittle and shatters below 0°C. |

♻️ 100% Virgin Material & Recyclability

Primary Quality: GREEN TPU films are manufactured using 100% virgin (primary) raw materials. We do not use secondary or recycled content in our film production, ensuring consistent performance, high cleanliness, and superior physical properties for your applications.

Secondary Recycling: However, because TPU is a Thermoplastic, it is fully recyclable at the end of its lifecycle. Scraps from your production process or used products can be collected, regranulated, and re-processed into other secondary products (such as shoe soles, injection molded parts, or mats), supporting a circular economy without waste. Discover more about our eco-friendly material initiatives.

Why Partner with GREEN TPU?

We are more than a supplier; we are a direct TPU film factory and strategic partner for diverse industrial applications. By controlling the entire lifecycle from raw materials to export, we ensure the quality, compliance, and stability your global business demands.

FAQ

Q: What is your Minimum Order Quantity (MOQ)?

A: Our MOQ for custom orders is 1000KG. For specific stock items, please check our MOQ policy.

Q: Do you offer OEM & ODM services?

A: Yes, we provide full OEM/ODM customization for thickness, color, and performance.

Q: Do you provide sample services?

A: Yes, we provide free samples for validation. You only need to cover the shipping cost.