Top Applications of TPU Hot Melt Adhesive Film: A Guide for Manufacturers

Bonding solutions for textile, shoe uppers & car interiors. Our TPU films offer superior strength, elasticity, and durability for manufacturing.

Introduction

In the competitive landscape of modern manufacturing, the shift from solvent-based glues to thermoplastic polyurethane films (TPU Films) is not just a trend—it is a necessity. As global standards for environmental safety (REACH, RoHS) tighten, manufacturers in textile, automotive, and footwear industries are turning to TPU hot melt adhesive films for their superior performance and eco-friendly properties.

At GREEN TPU, we don't just supply materials; we provide bonding solutions. This guide explores the versatile applications of TPU films, backed by our factory's decades of extrusion experience.

What is TPU Hot Melt Adhesive Film?

TPU hot melt adhesive film is a solvent-free, thermoplastic bonding material that melts when heated and solidifies upon cooling to create a strong physical bond. Unlike liquid glue, it ensures uniform thickness and eliminates drying time.

Key Properties:

- 100% Solid Content: No water or solvents, meaning zero shrinkage.

- Eco-Friendly: Low VOCs (Volatile Organic Compounds), making it safe for operators and end-users.

- Versatility: Compatible with diverse substrates including tpu laminated fabric, leather, foam, and plastics.

Core Application 1: The "Seamless" Revolution in Textiles

The apparel industry is our largest sector, particularly for high-performance sportswear and intimate apparel.

1. Seamless Underwear & Yoga Wear

Traditional stitching creates friction points. Our high elasticity TPU film solves this by enabling "No-Sew" technology.

- Soft Touch: The film bonds fabric layers while maintaining the original hand-feel (soft touch tpu).

- Stretch Recovery: It moves with the body. Our films offer elongation rates of over 400%, ensuring the garment doesn't deform after stretching.

- Wash Resistance: A critical metric. Our washable adhesive films withstand 40+ cycles of machine washing at 60°C without peeling.

2. Outdoor Gear & Waterproof Clothing

For jackets and ski suits, water resistance is non-negotiable.

- Seam Sealing: We use tpu tape to seal needle holes, ensuring the garment is 100% waterproof.

- Breathability: Our films balance adhesion with moisture vapor transmission, maintaining the breathable nature of the base fabric.

Pro Tip: For delicate fabrics like silk or lycra, we recommend using a low melt TPU film (activating at 60°C-80°C) to prevent fabric damage during lamination.

Core Application 2: Automotive Interiors (Smart Bonding)

With the rise of electric vehicles (EVs), the standard for cabin air quality has skyrocketed. Automotive interior hotmelt solutions are essential for reducing "New Car Smell" (VOCs).

Below represents how our TPU film performs in various car components:

| Component | Application Details & Requirements |

|---|---|

| Headliners (Roof) | Application: Bonding fabric to foam backing. Key Requirement: High Heat Resistance (>100°C) to withstand solar heat. |

| Door Panels | Application: Laminating synthetic leather or soft-touch fabrics. Key Requirement: Deep draw capability & Vacuum forming compatible. |

| Carpet & Insulation | Application: Attaching sound-deadening pads to the chassis. Key Requirement: Strong adhesion to rough and uneven surfaces. |

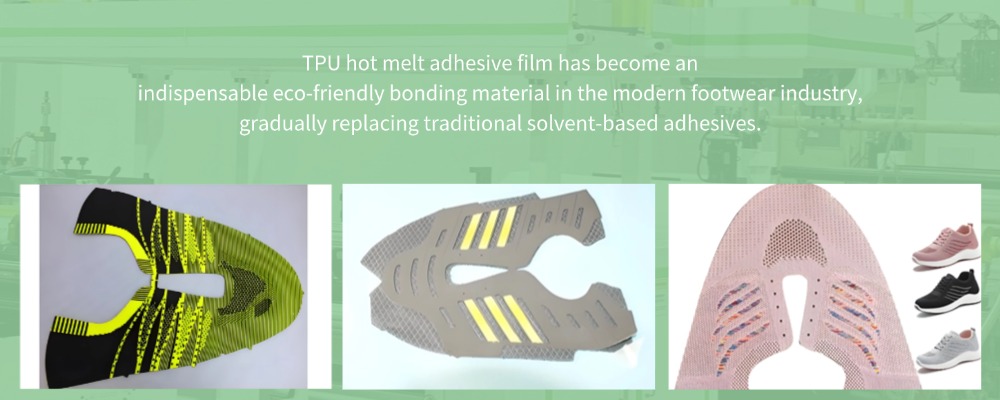

Core Application 3: Footwear Manufacturing

The shoe industry is demanding lighter, stronger, and more automated materials. TPU film for shoes is the answer.

- No-Sew Shoe Uppers: Replacing stitching on Flyknit or mesh uppers reduces weight significantly. The transparent tpu film can also act as a protective layer against abrasion.

- Heel Counters: Using stiffer, high-hardness TPU to provide structural support without the weight of traditional plastic counters.

- Advantage: Excellent resistance to hydrolysis (sweat) and yellowing (anti-yellowing tpu).

| ||

|  | |

Technical Selection: Which Series is Right for You?

Not all films are created equal. Choosing the correct melting point is crucial for your specific machinery. Here is a quick comparison guide:

| Series Name | Technical Specifications |

|---|---|

| Low Melt Series | Melting Range: 55°C - 80°C Key Characteristic: Fast activation, protects sensitive fabrics. Ideal Industry: Seamless Underwear, Delicate Textiles. |

| Medium Melt Series | Melting Range: 85°C - 110°C Key Characteristic: Balanced performance, widely used standard. Ideal Industry: Footwear, General Lamination, Embroidery. |

| High Melt Series | Melting Range: 115°C - 150°C Key Characteristic: Maximum durability and heat resistance. Ideal Industry: Automotive Interiors, Fire-retardant materials. |

Note: As a customized tpu film company, GREEN TPU can adjust these parameters (Thickness: 0.03mm-2.0mm) to fit your production line.

Emerging Applications: Electronics & Medical

Beyond the "Big Three" industries, TPU is finding new homes due to its unique barrier properties.

- Inflatable Products: For tpu inflatable air mattresses and life vests, our films provide excellent air-tightness and burst strength.

- Medical Devices: Medical grade polyurethane film is used in surgical drapes due to its biocompatibility and barrier properties against bacteria.

- Electronics: Used for bonding conductive fabrics or waterproofing mobile device components (waterproof flexible material).

| ||

|  | |

FAQ

Q: Is TPU hot melt film eco-friendly?

A: Yes. It is a thermoplastic polyurethane which is recyclable. Unlike PVC, it contains no plasticizers or phthalates and is REACH/RoHS compliant.

Q: Does the film turn yellow over time?

A: Standard TPU may yellow due to UV exposure. However, GREEN TPU offers specialized anti-yellowing (Grade 4-5) formulas specifically for visible parts like shoe uppers.

Conclusion: Partner with a Trusted Manufacturer

The quality of your final product depends on the quality of the bond. Whether you are making seamless yoga pants or automotive door panels, consistent material quality is key.

GREEN TPU offers:

- ISO-Certified Manufacturing

- Global Testing Standards (ASTM, JIS, ISO)

- Rapid Prototyping support

Ready to optimize your production line?

Contact us today to discuss your application and request a technical data sheet (TDS)