The Ultimate Guide to Choosing TPU Film Thickness: Balancing Performance & Application

Selecting the right thickness (Gauge) is the first and most critical step in TPU film application. Too thin, and you risk puncture; too thick, and you lose flexibility and increase costs. At GREEN TPU, we offer precise thickness customization from 0.01mm to 2.5mm. This guide explores how thickness impacts performance across medical, outdoor, and industrial sectors.

1. The Logic: How Thickness Affects Performance

Before diving into specific products, it is crucial to understand the trade-offs involved in thickness selection:

- ⚖️ Strength vs. Flexibility: Increasing thickness enhances Tensile Strength and Puncture Resistance, but reduces flexibility and "hand feel." For wearable products, finding the "Goldilocks zone" is key.

- 🔥 HF Welding: For inflatable products, thickness determines welding parameters. Films thinner than 0.1mm require high-precision equipment, while films thicker than 0.5mm need longer dwell times.

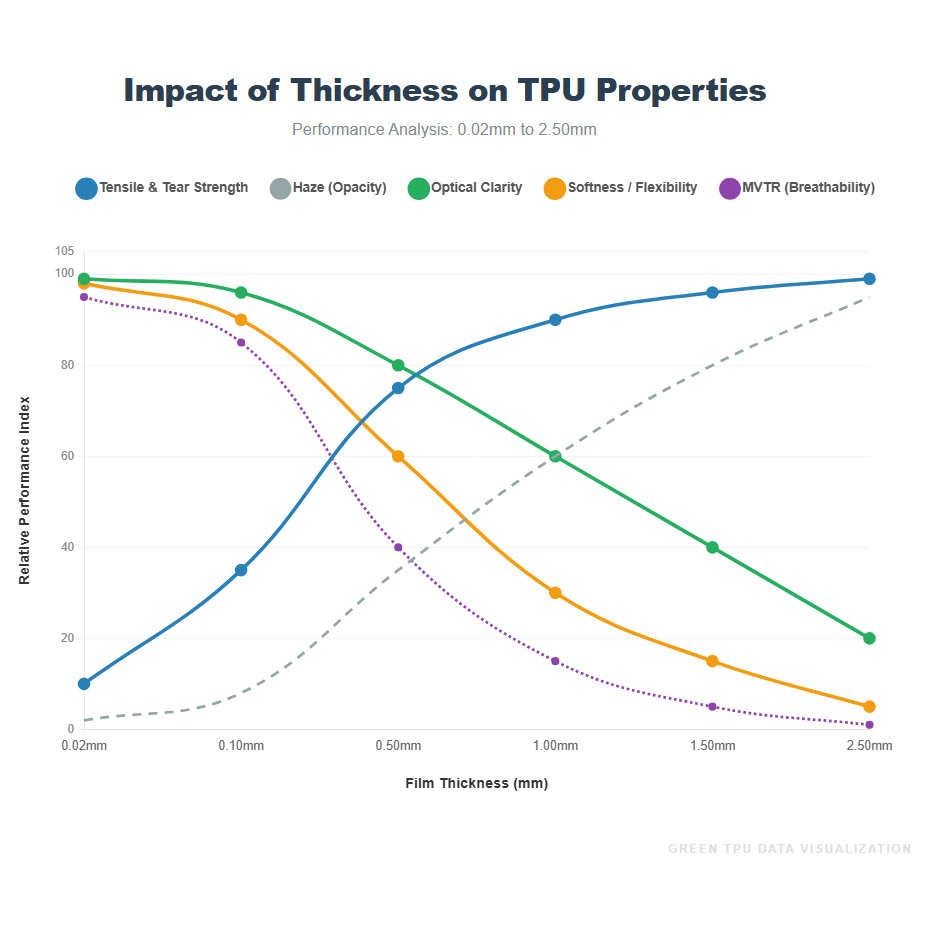

2. Visualizing Performance: Thickness vs. Strength

The chart below illustrates the relationship between TPU film thickness and key physical properties. As thickness increases, durability improves, but flexibility decreases.

⚠️ Engineering Note:

This chart demonstrates general physical trends based on standard Polyether TPU. Actual values may vary depending on:

- 1. Material Formula: Specific additives (e.g., UV stabilizers) can alter optical clarity.

- 2. Hardness (Shore A/D): Harder grades (e.g., 95A) retain less flexibility than softer grades (e.g., 80A) at the same thickness.

- 3. Processing Method: Extrusion calibration significantly affects haze and uniformity.

* Data provided by GREEN TPU Lab for reference purposes only.

3. Recommended Thickness by Application

Based on our 14 years of manufacturing experience, here are the industry-standard recommendations:

A. Textile Lamination & Apparel

B. Medical Airbags & Devices

C. Inflatables & Outdoor Gear

D. Industrial & Protection

4. Quick Selection Summary Table

5. Quality Control & Inspection Standards

Consistency in thickness is the hallmark of a quality TPU manufacturer. At GREEN TPU, we employ rigorous testing methods.

Online Thickness Gauge

We utilize an advanced Online Thickness Gauge system during extrusion. This ensures the Thickness Tolerance is controlled within ±0.01mm.

Physical Property Testing

Every batch undergoes tensile strength, elongation at break, and tear resistance testing in our lab before shipment, adhering to ASTM D412 standards.

Visual Inspection

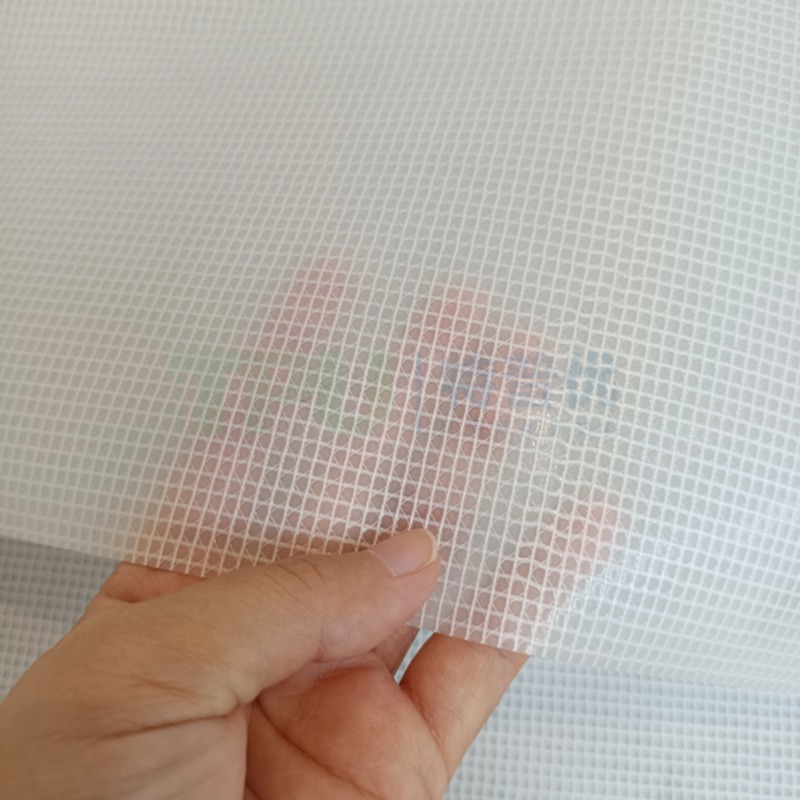

Manual and automated visual checks to ensure the film surface is free from crystal points, bubbles, or black spots (impurities).

6. Frequently Asked Questions (FAQ)

Does thickness affect transparency?

Yes, slightly. Thicker films (e.g., >1.0mm) may appear slightly hazier than thin films (0.1mm), especially for matte finishes. However, our high-transparency series maintains excellent optical clarity even at higher thicknesses.

What is the tolerance for custom thickness?

For films under 0.5mm, our standard tolerance is ±0.01mm. For thicker films (above 0.5mm), the tolerance is typically ±2-3%. We can provide tighter tolerances upon request.

Can I mix different thicknesses in one order?

Yes, you can. However, each thickness specification usually has a Minimum Order Quantity (MOQ). Please contact our sales team to discuss your specific combination.

Why Choose GREEN TPU?

Choosing the right thickness is only half the battle. You also need a manufacturer who can guarantee consistency. At GREEN TPU, our ISO 9001 certified process ensures you get the exact spec you ordered.

Need a sample kit to feel the thickness yourself?

Request Free Thickness Sample Kit